Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

As we move towards 2025, the cutting machine industry is poised for significant advancements that promise to enhance operational efficiency across various sectors. According to the latest market report by Research and Markets, the global cutting machine market is projected to grow from $4.2 billion in 2023 to over $6.5 billion by 2025, fueled by demand for precision and speed in manufacturing processes. Such growth underscores the critical importance of adopting cutting-edge technology to stay competitive.

Expert insights also highlight the evolving landscape of cutting machines. Dr. Emily Thompson, a leading authority in manufacturing technology, noted, "The future of cutting machines lies in integrating smart technology and automation, which not only optimizes performance but also reduces waste and operational costs." This sentiment reflects a broader trend within the industry, where the focus is shifting towards machines that enhance productivity while maintaining sustainability.

In this context, exploring the top cutting machines set to dominate in 2025 is essential for businesses aiming to leverage these advancements. Implementing innovative cutting solutions will not only improve efficiency but also significantly impact overall productivity in manufacturing and beyond.

As we look ahead to 2025, the landscape of cutting machine technology is rapidly evolving. One of the most significant trends is the increased integration of artificial intelligence and machine learning, which are set to enhance operational efficiency and precision in cutting processes. Advanced algorithms can optimize cutting patterns, reducing waste and improving material utilization. Additionally, AI-driven predictive maintenance will ensure machines run smoothly, significantly reducing downtime and enhancing productivity.

Another key trend is the rise of automation and smart manufacturing. With the advent of IoT (Internet of Things), cutting machines are becoming smarter, allowing for real-time monitoring and data analysis. This connectivity enables manufacturers to gather insights into performance metrics, facilitating timely adjustments and informed decision-making. Furthermore, sustainability is gaining traction, with cutting machines designed for energy efficiency and reduced environmental impact, aligning with global efforts toward greener manufacturing practices.

These emerging trends promise to redefine efficiency in the cutting machine sector, setting the stage for significant advancements in the years to come.

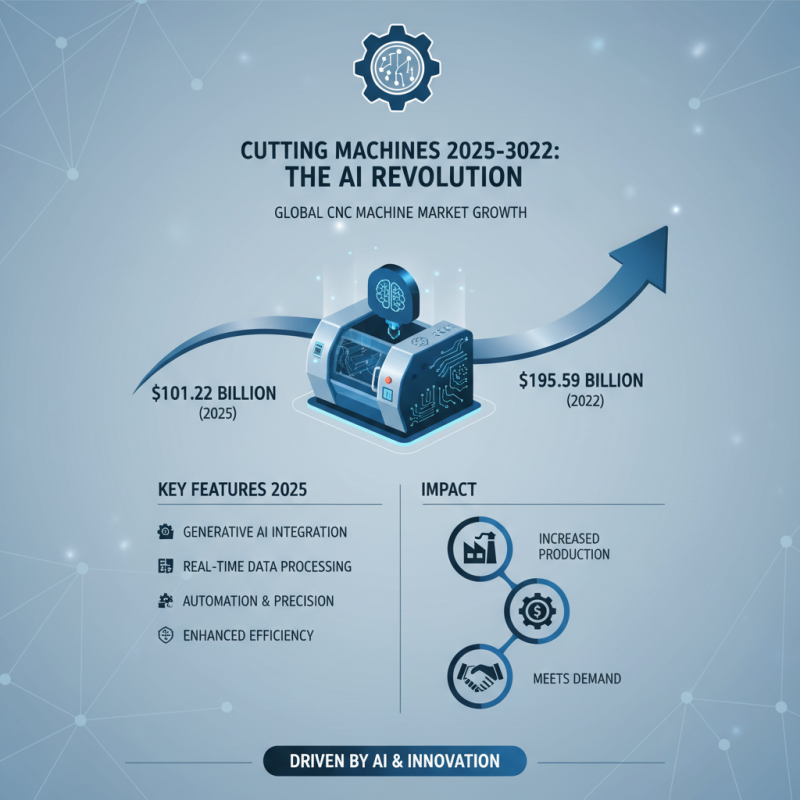

In 2025, cutting machines are poised to incorporate advanced features that significantly enhance efficiency, driven in part by the growing integration of generative AI technologies. With the global market for CNC machines projected to escalate from $101.22 billion in 2025 to approximately $195.59 billion by 2032, manufacturers are under pressure to innovate. Key functionalities such as real-time data processing and automation through AI are essential to meet the increasing demand, marking a substantial shift in how cutting machines operate.

Energy efficiency is another critical component as manufacturers strive to meet environmental standards while maximizing production capabilities. The concept of "energy efficiency" as the "first fuel" underscores its role in reducing operational costs and carbon footprints. The laser cutting machine segment exemplifies this trend, using minimal resources to achieve high precision. As companies adopt these cutting-edge solutions, not only do they improve their bottom line, but they also position themselves as leaders in sustainable manufacturing practices. The landscape in cutting technologies will be redefined by these advancements, making 2025 a pivotal year for industry evolution.

As we look ahead to 2025, the cutting machine market is anticipated to witness significant advancements, driven by top brands that are pushing the boundaries of technology. The global CNC machine market alone is expected to escalate from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, highlighting a robust growth rate of 9.9%. This growth underscores the increasing demand for precision and efficiency in manufacturing processes, which cutting machines directly address.

In the realm of craft and hobby projects, laser cutters and engravers are also gaining traction, with many users seeking versatile machines that can handle a range of materials. For those looking for alternatives to common crafting machines, several brands have emerged with innovative options designed for cutting vinyl, paper, fabric, and more. These developments are not only making crafting more accessible but also enhancing the creative possibilities for individuals and small businesses alike. With the introduction of the latest generation of craft cutters, users can expect a seamless blend of performance and user-friendly features to boost their creative endeavors.

This chart illustrates the efficiency ratings of various cutting machines anticipated for 2025. Each type of cutting machine showcases its expected performance level, providing insights for industries looking to enhance their cutting processes.

As we look forward to 2025, the cutting machine industry is poised for remarkable innovations that promise to boost productivity across various sectors. According to a recent report by Markets and Markets, the global cutting machine market is expected to reach USD 4.85 billion by 2025, growing at a CAGR of 4.7%. This growth is significantly driven by advancements in automation and technology that enhance the efficiency of cutting processes. New machine designs integrated with IoT capabilities allow for real-time data monitoring, enabling businesses to optimize their operations and reduce waste.

Moreover, the introduction of AI-powered cutting machines is revolutionizing the industry by improving precision and speed. According to a study published by Technavio, the implementation of AI in manufacturing could lead to productivity gains of up to 30%. These machines utilize machine learning algorithms to analyze cutting patterns and proactively adjust parameters to ensure optimal performance, ultimately reducing downtime. As businesses continue to seek ways to improve their operational efficiency, investing in these innovative cutting machines will be critical for maintaining a competitive edge in the market.

The impact of automation on cutting machine performance in 2025 is poised to be transformative, significantly enhancing efficiency and precision across various industries. As AI technologies continue to advance, cutting machines will increasingly incorporate smart manufacturing systems that enable real-time monitoring and predictive maintenance. This shift not only streamlines operations but also reduces downtime, allowing businesses to operate at peak productivity levels.

Moreover, the growing demand for precision in manufacturing processes necessitates the integration of automated cutting solutions. Industries such as automotive and agriculture are already experiencing the benefits of automation, with advanced cutting machines tailored to meet the unique demands of these sectors. By embracing automation, companies can achieve higher reliability in their cutting operations, which is crucial for maintaining competitive advantage in the market.

As companies invest in these technologies, we can anticipate a significant evolution in cutting machine capabilities, leading to improved overall performance and operational efficiency by 2025.