Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

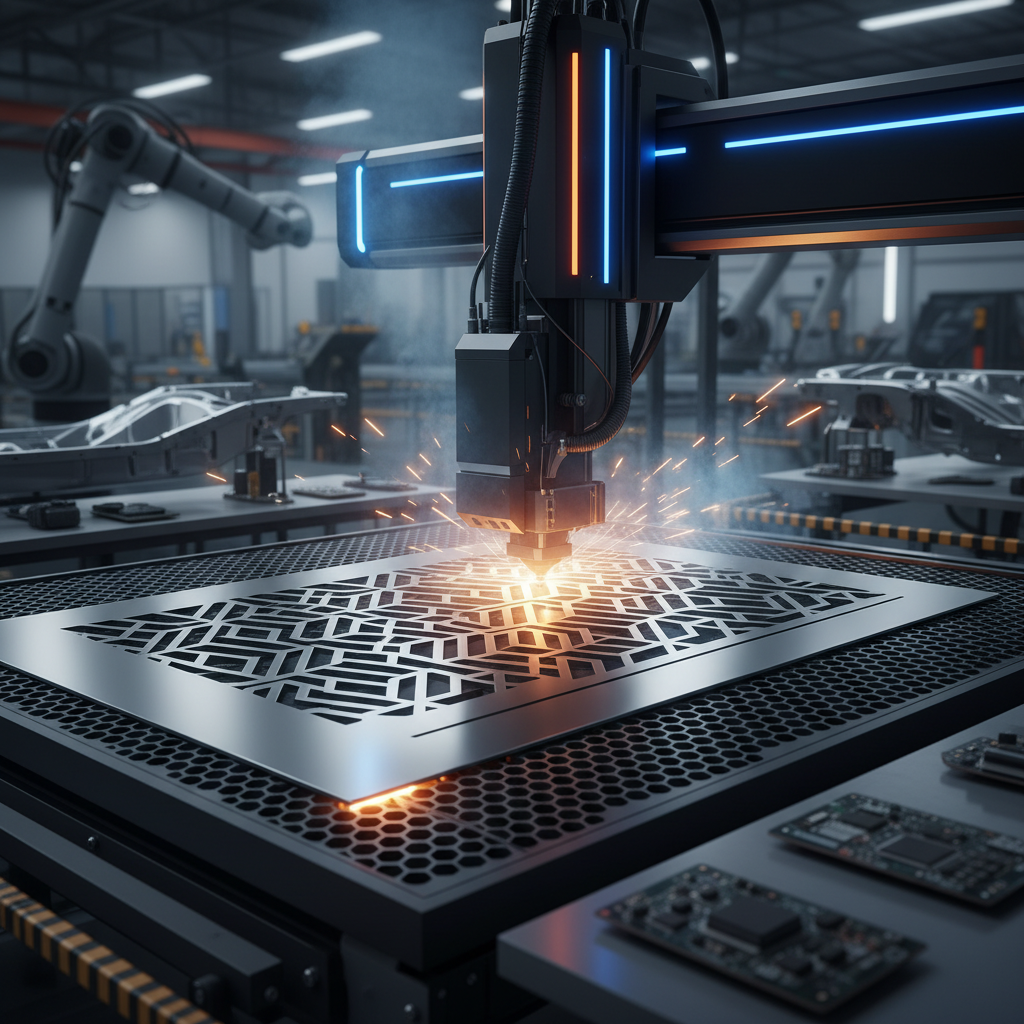

In today's fast-paced manufacturing landscape, businesses are constantly seeking ways to enhance efficiency and reduce costs. One revolutionary tool making waves in the industry is the

Automatic Cutting Machine. According to industry expert John Smith, a leader in automation technology,

"The integration of an Automatic Cutting Machine not only streamlines operations but also significantly improves precision and productivity."

His insights encapsulate the essence of why these machines are becoming indispensable in various sectors, from textiles to automotive manufacturing.

The advantages of adopting an Automatic Cutting Machine are numerous and impactful. Businesses can benefit from

reduced labor costs, minimized material waste,

and the ability to produce high-quality products at scale. As more companies realize the profound benefits and

return on investment that come with automation, the question of

"Why should we invest in an Automatic Cutting Machine?" becomes increasingly pressing. This exploration of the

top 10 benefits highlights how embracing this technology can transform operations and drive success in a competitive market.

Automatic cutting machines have revolutionized various industries by offering unparalleled precision and accuracy in material processing. According to industry reports, the global laser cutting machine market is expected to reach approximately $5 billion by 2025, driven by advancements in technology and increasing demand across sectors such as automotive, aerospace, and electronics. The ability of these machines—whether they utilize fiber, CO2, or solid-state lasers—to produce intricate designs with minimal waste enhances operational efficiency significantly.

Furthermore, the ongoing COVID-19 pandemic has accelerated the adoption of automated solutions as businesses seek to optimize productivity while minimizing human intervention. In particular, sectors relying on high-volume production have shifted towards fully automated systems, reflecting a growing trend towards robotic solutions in cutting technology. Reports indicate that the demand for robotic cutting machines is likely to see a substantial surge, with forecasts suggesting a CAGR of over 6% in the coming years. This shift not only ensures accuracy but also addresses the challenges posed by labor shortages and fluctuating workforce dynamics post-pandemic.

The advancement of technology in manufacturing has led to the widespread adoption of automatic cutting machines, which dramatically enhance production efficiency. According to a report by MarketsandMarkets, the automatic cutting machinery market is projected to reach $8.1 billion by 2025, reflecting a consistent growth trajectory as businesses seek ways to optimize their operations.

Automating the cutting process allows companies to reduce labor costs significantly while decreasing material wastage, thereby improving the overall bottom line. By employing automated systems, businesses can achieve cutting speeds that are up to 10 times faster than manual methods, drastically reducing lead times and facilitating just-in-time production.

Moreover, automatic cutting machines offer unparalleled precision and consistency, which is vital in industries where tight tolerances are necessary. A study from the Fabricators and Manufacturers Association indicates that automated cutting can enhance product accuracy by up to 90%, minimizing the chances of errors that can lead to costly rework. Furthermore, integrating advanced software solutions with cutting machines enables real-time monitoring and data analysis, providing insights that can further streamline operations. As such, embracing automated cutting solutions not only boosts productivity but also positions companies to remain competitive in an ever-evolving market landscape.

Investing in an automatic cutting machine can significantly reduce labor costs for businesses in various industries. Traditional cutting processes often rely on a workforce skilled in manual techniques, which can be both time-consuming and costly. By automating these tasks, companies can streamline their operations and reduce the need for a large labor force dedicated to cutting materials. This not only saves on wages but also minimizes training expenses associated with maintaining an experienced workforce.

Moreover, automatic cutting technology enhances efficiency and productivity, allowing businesses to allocate their human resources to more value-added tasks. With faster and more precise cutting, the turnaround time for projects is dramatically decreased, which can improve overall service delivery. As a result, businesses can focus on scaling their operations without the corresponding increase in labor costs, ultimately leading to higher profit margins. Embracing automatic cutting solutions is a strategic move for companies looking to optimize their operations and remain competitive in their respective markets.

Automatic cutting machines offer significant advantages for businesses looking to optimize their material utilization and minimize waste. According to a report by **Smithers Pira**, companies can achieve up to a 30% reduction in material waste by implementing advanced cutting technologies. This is crucial in industries like textiles and manufacturing, where excess materials can lead to increased costs and environmental impact. By utilizing precise cutting capabilities, businesses can maximize the use of raw materials, ensuring that less is discarded and more is transformed into finished products.

Implementing an automatic cutting machine not only enhances efficiency but also improves accuracy, leading to better product quality. For instance, **the International Textile Manufacturing Society** has highlighted that businesses adopting automated systems see a 20% increase in cutting precision. This means fewer returns and wastage due to defects, ultimately saving money and time.

**Tips**: When investing in an automatic cutting machine, consider evaluating your current material usage to identify areas for improvement. Regular training for staff is also essential to keep up with the machine's capabilities and maximize productivity. Lastly, always monitor the performance of your cutting machine to adjust for material types and thicknesses, ensuring optimal results.

The integration of automatic cutting machines into business operations significantly enhances safety standards in work environments. By automating the cutting process, these machines reduce the risk of accidents associated with manual cutting, such as injuries from sharp blades or repetitive strain injuries from prolonged use. Workers are less likely to be exposed to hazardous conditions, as the machines take over high-risk tasks, allowing employees to focus on more strategic and safer roles.

Moreover, automatic cutting machines often come with advanced safety features, such as emergency stop functions, protective covers, and sensors that detect operator presence. These features contribute to a safer workplace by minimizing human error and ensuring that equipment operates within designated safety protocols. As businesses prioritize safety, the use of innovative technology not only enhances overall workplace safety but also boosts employee morale and productivity, as workers feel more secure in their roles.

Embracing automation in cutting processes represents a forward-thinking approach that aligns with contemporary safety standards and fosters a culture of care within the workplace.