Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

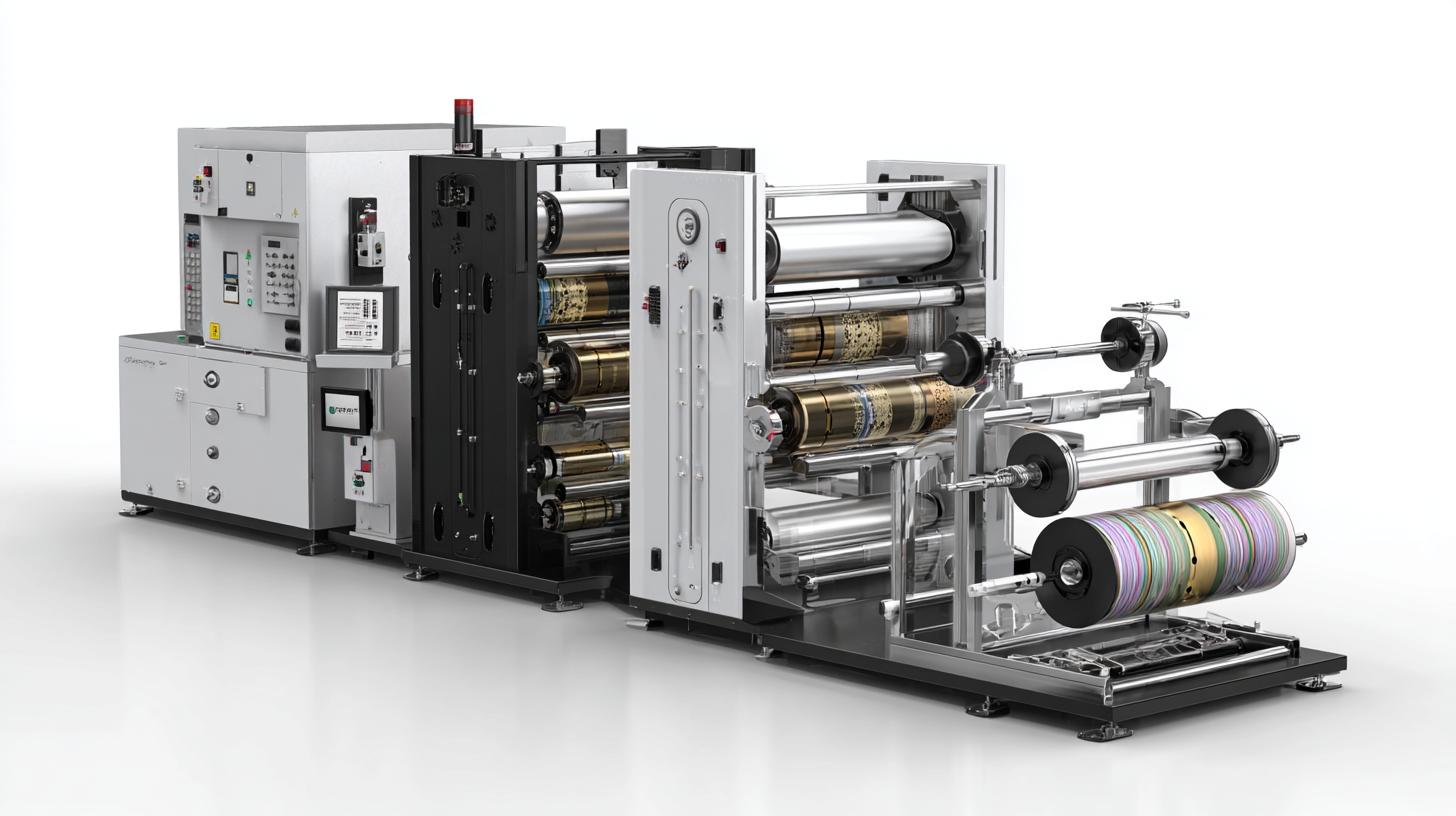

In the competitive landscape of modern printing, the Hot Foil Embossing Machine has emerged as a transformative tool that significantly enhances print quality and operational efficiency. According to recent industry reports, businesses implementing hot foil embossing have witnessed an up to 75% improvement in productivity while achieving intricate designs with unparalleled precision. The ability to apply metallic finishes and raised textures not only elevates the aesthetic appeal of printed materials but also contributes to brand differentiation in a crowded market. As the demand for high-quality, customized products continues to rise, leveraging the capabilities of a Hot Foil Embossing Machine has become essential for printers seeking to stay ahead. This guide will explore the effective strategies for maximizing the potential of hot foil embossing, positioning your print operations for success in an increasingly visual-driven economy.

Hot foil embossing is a sophisticated printing technique that combines heat, pressure, and metallic foils to create striking designs on various substrates. This process not only enhances the aesthetic appeal of printed materials but also offers a lightweight and cost-effective solution for high-quality finishes. By using specialized machines, brands can achieve intricate designs that captivate the audience's attention while maintaining durability and resistance to wear and tear.

One of the standout benefits of hot foil embossing is its ability to significantly boost print quality with remarkable efficiency. By utilizing this technology, businesses can achieve up to 75% more efficiency compared to traditional printing methods. The precision of hot foil embossing allows for consistent results, reducing waste and production time. Additionally, the variety of foils available—ranging from metallics to holographics—enables companies to tailor their packaging and promotional materials, ultimately leading to enhanced brand recognition and customer engagement.

Hot foil embossing machines have revolutionized the printing industry, offering a sharp edge in print quality and efficiency. By applying heat and foil to substrates, these machines create stunning designs with a glossy finish that traditional printing methods struggle to achieve. Key features of these machines include precise temperature control, adjustable pressure settings, and rapid setup times, all of which contribute to enhanced print quality and consistency. Users can expect to achieve a print quality boost of up to 75%, transforming ordinary projects into extraordinary works of art.

Hot foil embossing machines have revolutionized the printing industry, offering a sharp edge in print quality and efficiency. By applying heat and foil to substrates, these machines create stunning designs with a glossy finish that traditional printing methods struggle to achieve. Key features of these machines include precise temperature control, adjustable pressure settings, and rapid setup times, all of which contribute to enhanced print quality and consistency. Users can expect to achieve a print quality boost of up to 75%, transforming ordinary projects into extraordinary works of art.

Tips:

To maximize the benefits of hot foil embossing, ensure that your substrates are compatible with the foils used. Conducting preliminary tests can help determine the best combination for achieving optimal results. Additionally, regularly maintaining your machine will prevent downtime and preserve quality output.

Another notable feature is the versatility of hot foil embossing machines, which can handle a variety of materials, including paper, cardboard, and even leather. This adaptability allows businesses to expand their product offerings and cater to diverse customer needs. When choosing the right machine, consider investing in one with advanced digital controls for enhanced precision and ease of use, ensuring that you can deliver top-notch quality consistently.

Tips:

Always keep a log of your settings and results. This documentation will assist in replicating successful runs and troubleshooting any issues that may arise.

Hot foil embossing has emerged as a transformative printing technique, surpassing traditional methods in both aesthetic appeal and operational efficiency. A comparative analysis reveals that hot foil embossing can enhance print quality while optimizing processes by up to 75%. According to a report by Smithers Pira, the global market for embossing technologies is projected to grow at a compound annual growth rate (CAGR) of 6.8%, underscoring the increasing preference for refined finishing techniques over conventional printing.

When contrasting hot foil embossing with traditional printing methods such as offset or digital printing, the advantages become clear. For instance, hot foil embossing employs heat and pressure to transfer metallic foil onto substrate surfaces, resulting in striking, reflective designs that are often unattainable with traditional methods. The versatility of hot foil embossing also enables its application across various materials, lending itself well to packaging, greeting cards, and high-end marketing materials. A study from the Paper and Packaging Board indicates that consumer attention can increase by up to 70% when high-quality finishes like foil stamping are employed, further validating the shift towards superior printing techniques that captivate audiences and elevate brand presence.

Hot foil embossing machines have been revolutionizing the printing industry, providing enhanced print quality and efficiency. Several case studies underscore their real-world applications and benefits. For instance, a packaging company reported a 75% increase in production efficiency after integrating a hot foil embossing system into their workflow. This improvement not only elevated the aesthetic appeal of their products but also allowed for quicker turnaround times, resulting in higher customer satisfaction and increased sales.

In another case, a luxury greeting card manufacturer adopted hot foil embossing to differentiate their products in a saturated market. By implementing this technology, they achieved a 60% cost reduction in production while enhancing the embossed designs' clarity and shine. Industry reports indicate that businesses utilizing hot foil embossing can see up to a 20% boost in perceived product value, making it an attractive option for designers and marketers alike.

Tips: When considering hot foil embossing, it's crucial to choose the right substrate. Not all materials respond well to embossing techniques, so test samples are recommended. Additionally, collaborate closely with your foil supplier to select the perfect color and finish that aligns with your brand’s identity, enhancing the overall quality and effectiveness of the embossed designs.

To maximize the efficiency of hot foil embossing machines, adhering to best practices is essential. First and foremost, it's crucial to maintain the machine in optimal condition. Regular cleaning and scheduled maintenance can prevent malfunctions and ensure that the foil is applied evenly, thus enhancing print quality. Additionally, using the right foil type for your specific material can significantly impact the final product's appearance and durability.

Tip: Always run a test imprint on scrap material before starting a production batch. This helps identify any issues with foil adhesion or alignment, saving time and resources in the long run.

Furthermore, careful calibration of pressure and temperature settings allows for a more controlled embossing process. Understanding the material characteristics and how they react to heat and pressure can lead to better results. Proper training for operators will also enhance their skill in managing the machine effectively.

Tip: Keep a detailed log of all settings and outcomes for different projects. This data can serve as a reference for future jobs, helping to streamline the process and maintain high standards.

| Feature | Description | Efficiency (%) | Print Quality Rating (1-10) | Best Practice |

|---|---|---|---|---|

| Heat Settings | Optimal temperature for foil adherence | 75 | 9 | Maintain consistent heat |

| Foil Type | Choosing the right foil for your project | 70 | 8 | Test different foils |

| Pressure Settings | Adjusting pressure for optimal results | 80 | 10 | Regularly calibrate pressure |

| Speed Settings | Velocity of operation for efficiency | 85 | 9 | Optimize production runs |

| Maintenance | Regular upkeep for longevity | 90 | 10 | Schedule routine maintenance checks |