Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the ever-evolving world of manufacturing, selecting the right printing machine industrial is crucial for efficiency and output quality. Experts suggest that the choice of equipment can significantly impact not only production capabilities but also the overall profitability of operations. Renowned industrial printing consultant, John Smith, emphasizes, “The machine you choose can define the quality of your products; it is essential to make an informed decision.”

When it comes to investing in an industrial printing machine, several factors must be considered. These include the specific printing technology needed, the types of materials being printed on, production speed, and the machine's maintenance requirements. As industries shift towards more sustainable practices, it is also important to evaluate the environmental impact of printing equipment. By understanding these elements and consulting with industry experts, businesses can make knowledgeable choices that align with their operational goals.

Ultimately, choosing the right printing machine industrial is not merely a purchase; it is a strategic decision that shapes the future trajectory of a company. By taking the time to evaluate these key factors, businesses can ensure they invest in machinery that not only meets their current demands but also adapts to future needs.

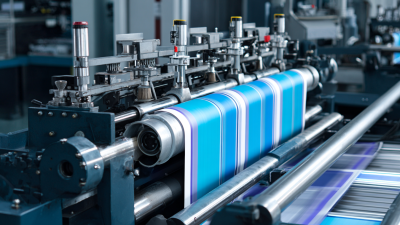

When selecting an industrial printing machine, it's crucial to evaluate key specifications that directly impact performance and efficiency. First, the printing speed is a vital factor, as it determines how quickly the machine can produce output. Higher speeds can lead to increased productivity, but it's also important to consider the quality of the print at those speeds. A balance between speed and quality is essential, especially for industries that require high-resolution images or detailed graphics.

Another critical specification to assess is the printing technology utilized by the machine. Different technologies, such as inkjet, laser, or offset printing, offer distinct advantages and limitations. Inkjet printers, for instance, are often preferred for their versatility and ability to produce vibrant colors, while laser printers excel in speed and are cost-effective for text-heavy documents. Additionally, it's vital to look into the media handling capabilities of the machine, which includes the size, type, and thickness of materials it can process. This can significantly affect your production capabilities and efficiency as well as the range of products you can offer to your clients.

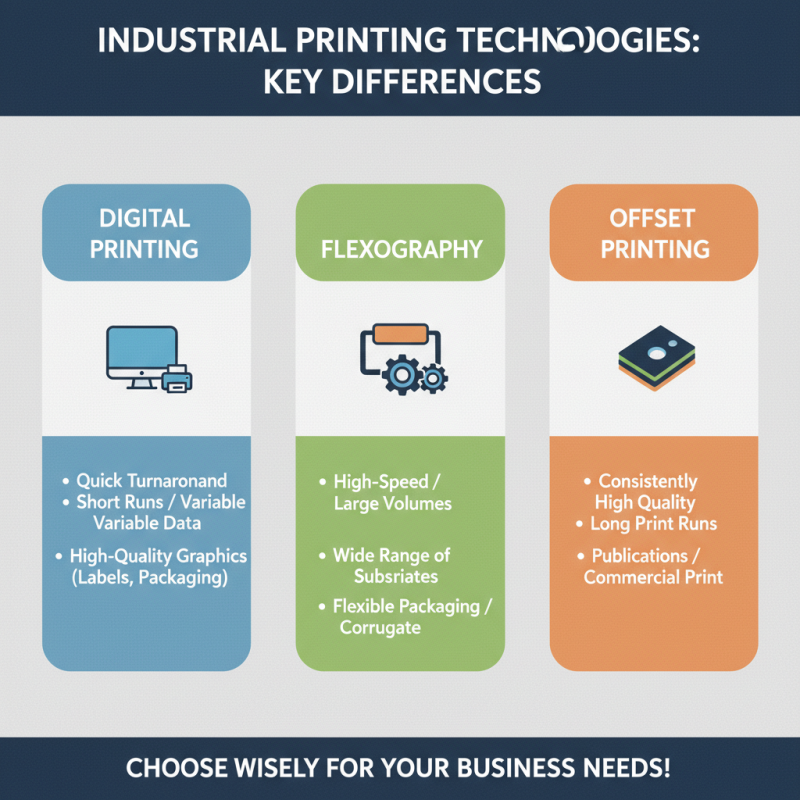

When selecting an industrial printing machine, understanding the different types of printing technologies available is crucial for making an informed decision. Among the most common technologies are digital printing, flexography, and offset printing. Digital printing offers flexibility and quick turnaround times, making it ideal for short-run jobs and variable data printing. This technology allows for high-quality images and graphics, which is particularly beneficial for products like labels, packaging, and promotional materials.

Flexography, on the other hand, is a relief printing process that employs flexible plates to print on various substrates, including plastic, paper, and cardboard. This method is known for its efficiency in long-run printing jobs and is widely used in packaging applications such as food products and consumer goods. Offset printing remains a stalwart in the industry due to its ability to produce high-quality prints with consistent results, particularly for larger print volumes. It is often chosen for tasks like brochures, magazines, and promotional materials, where quality and detail are paramount.

Selecting the appropriate printing technology depends on specific business needs, including print volume, material type, and desired quality. Each technology has its own strengths and is suited to different applications, making it essential to align the choice of printing machine with the intended use for optimal results.

When planning for the purchase of an industrial printing machine, cost considerations play a pivotal role in your decision-making process. Establishing a clear budget not only helps you narrow down your options but also ensures that you can invest in a machine that meets both your operational needs and financial capacity. Consider all associated costs, including installation, maintenance, and training. These factors can significantly influence the overall investment and should not be overlooked.

Tips: Always allocate a portion of your budget for unforeseen expenses. Industrial printing machines may require upgrades or additional accessories that can enhance their performance. By setting aside contingency funds, you can make informed decisions without compromising quality.

Additionally, it is essential to evaluate the long-term value of the equipment. While a lower initial cost might seem appealing, a more expensive machine with higher efficiency and lower operating costs could save you money in the long run. Conducting a thorough cost-benefit analysis can aid you in identifying which machine will provide the best return on investment over time.

Tips: Research industry trends and consider future scalability when selecting a printing machine. Investing in a more versatile model today can help accommodate your growing business needs while preventing the potential costs of replacing equipment in the near future.

When selecting an industrial printing machine, one of the crucial aspects to consider is the maintenance and support services offered by the manufacturers. Reliable support can significantly reduce downtime and enhance the productivity of your operations. A machine with excellent maintenance services ensures that any issues can be promptly addressed, allowing for consistent performance and minimizing disruptions. Look for manufacturers that provide comprehensive service packages, including routine maintenance checks and easy access to spare parts.

Tips: Before making a purchase, inquire about the response time for service requests and whether they offer remote support. This can be particularly beneficial for troubleshooting minor issues without needing a technician on-site, thus saving both time and costs.

Additionally, consider the training and resources available for your staff. A manufacturer that offers training sessions and technical documentation can make a substantial difference in how efficiently your team can operate the printing machine. Well-informed staff can handle minor maintenance tasks, which further reduces the dependency on external support.

Tips: Ask about the availability of online resources such as video tutorials or user forums. These can be invaluable for ongoing education and quick problem-solving in a pinch.

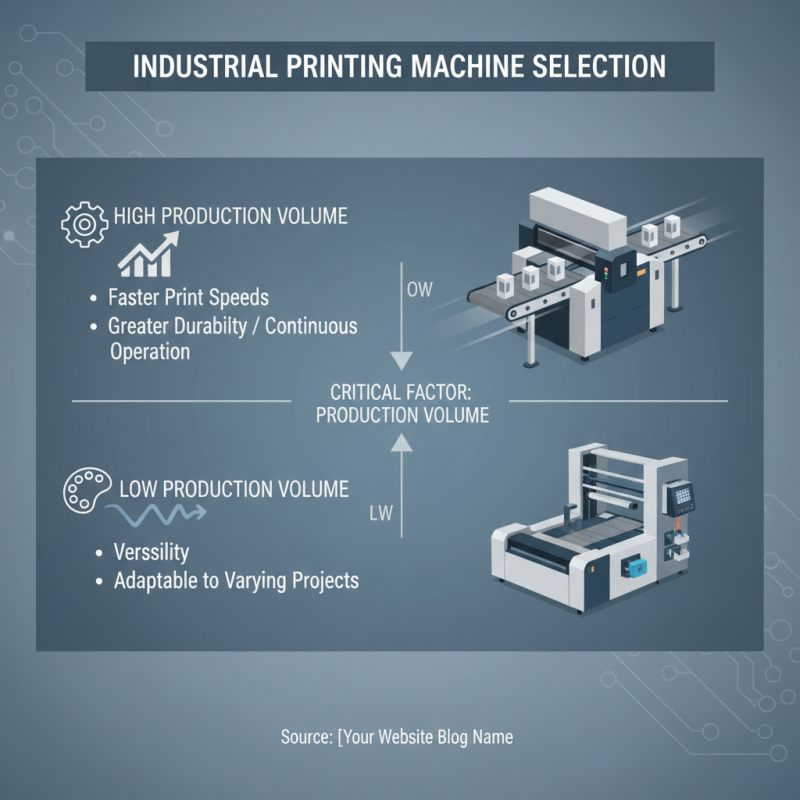

When selecting an industrial printing machine, one of the most critical factors to consider is the production volume. The volume of output required directly influences the type of machine suitable for the job. Higher production demands may necessitate more advanced machinery with faster printing speeds and greater durability, ensuring that the machine can sustain continuous operation without compromising on quality. In contrast, a lower production volume might allow for the selection of machines that prioritize versatility over speed, giving businesses the flexibility to adapt to varying project requirements.

Another aspect to consider is how production volume impacts machine performance over time. Machines designed for high-volume production typically incorporate robust components that can withstand the wear and tear associated with extensive usage. This makes them ideal for businesses anticipating steady or increasing workloads. Conversely, machines intended for lower volumes may be more economical initially but could face challenges related to speed and efficiency if required to handle unexpectedly high demands. Understanding the relationship between projected production volume and the specifications of the machine is essential for optimizing productivity and minimizing operational disruptions.