Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In today's rapidly advancing industrial landscape, cutting machines play a crucial role in enhancing efficiency and precision across various sectors. These versatile tools are designed to cut a wide range of materials, from textiles and metals to plastics and wood, thereby accommodating the diverse needs of industries such as manufacturing, construction, and automotive. As John Smith, a renowned expert in cutting technology, aptly stated, "The precision of a cutting machine not only increases productivity but also ensures the highest quality in finished products."

Understanding how cutting machines operate is essential for businesses seeking to optimize their operations and maintain a competitive edge. These machines utilize advanced technologies, including lasers, plasma, and water jets, to achieve clean cuts with minimal waste. The adaptability of cutting machines allows them to be tailored for specific tasks, making them invaluable assets in workshops and production lines. As we delve deeper into the functionality and applications of cutting machines, it becomes evident that their impact is profound and far-reaching, fundamentally reshaping how industries approach manufacturing and fabrication processes.

Cutting machines are essential tools in various industries, designed to perform the precise and efficient cutting of materials ranging from textiles to metals. These machines come in various forms, including

laser cutters, CNC routers, and plasma cutters, each tailored to specific applications. According to a report by MarketsandMarkets, the global cutting machine market is projected to grow from USD 3.5 billion in 2023 to USD 5.2 billion by 2028, emphasizing the increasing demand for advanced cutting technologies across sectors.

Understanding the different types of cutting machines is crucial for manufacturers and engineers looking to optimize their production processes.

Laser cutting machines, for instance, offer unparalleled precision and are widely used in automotive and aerospace industries for cutting complex geometries. CNC routers, on the other hand, are favored in woodworking and plastic fabrication, providing both speed and accuracy. A recent survey highlighted that 65% of manufacturers reported increased productivity after integrating CNC technologies into their operations, illustrating the significant role of cutting machines in enhancing efficiency.

Moreover, plasma cutting machines are utilized for their ability to cut through thick materials quickly, making them valuable in metal fabrication. The precise nature of these cutting techniques allows for minimal material wastage, which is a critical consideration in today's economy. Research from the Fabricators & Manufacturers Association International indicates that cutting technologies can improve material utilization by up to 20%, demonstrating the economic benefits that cutting machines bring to various manufacturing processes.

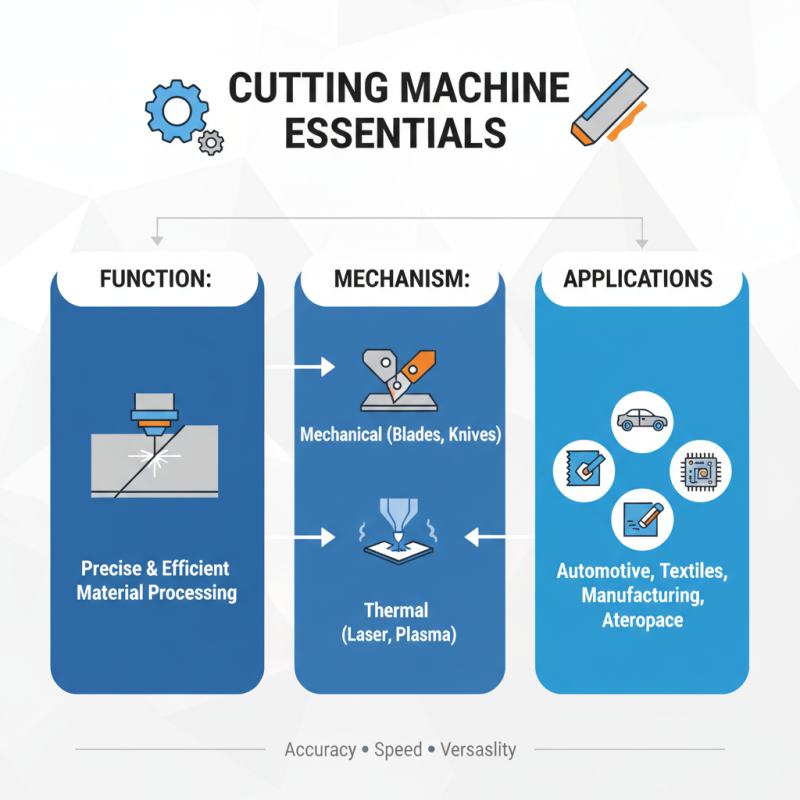

A cutting machine is an essential tool utilized across various industries for precise and efficient material processing. Its operational mechanism typically involves a sharp blade or laser that executes clean cuts with high accuracy. The machine's cutting action is driven by either mechanical or thermal processes, depending on the material requirements. For instance, mechanical cutting involves rotary knives or shear blades, while laser cutting utilizes focused light beams to melt, burn, or vaporize materials.

In many applications, such as the textile or metalworking industries, the cutting machine integrates advanced technology to optimize productivity. Computer numerical control (CNC) systems are often employed, allowing for automated precision cutting based on programmed designs. This technology not only enhances accuracy but also significantly reduces material waste, making operations more cost-effective.

Tips: When working with cutting machines, it’s crucial to maintain the blades for optimal performance, as dull blades can result in uneven cuts and increased safety hazards. Additionally, operators should be trained in safety protocols to prevent accidents. Always ensure that the workspace is clear of obstacles to facilitate smooth operation and enhance workplace safety.

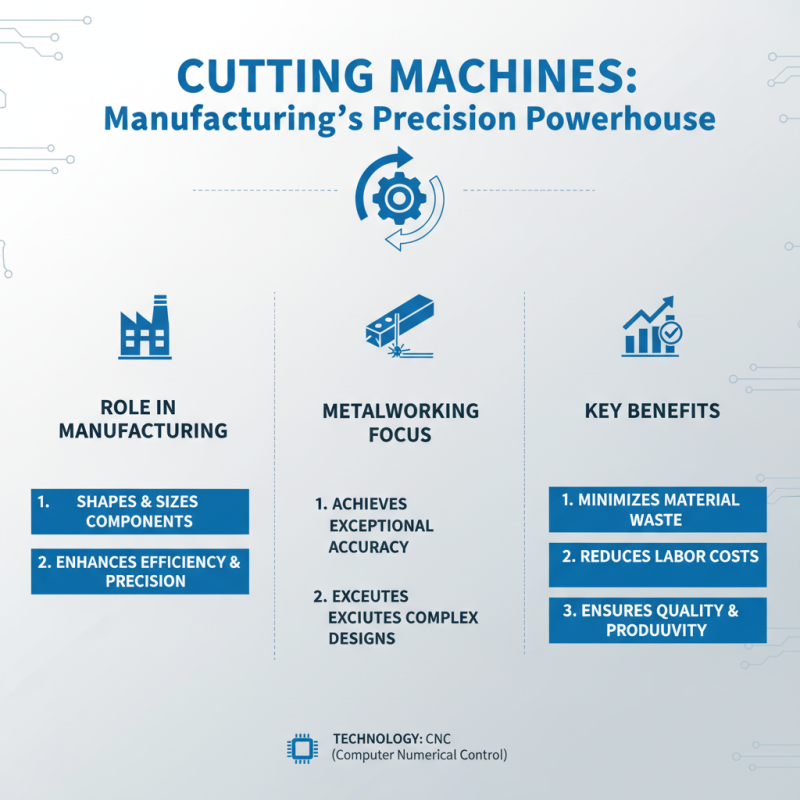

Cutting machines are integral to various manufacturing industries, playing a crucial role in enhancing efficiency and precision. In the metalworking industry, for instance, cutting machines are employed to shape and size metal components with exceptional accuracy. Techniques such as CNC (Computer Numerical Control) cutting allow for complex designs to be executed consistently, ensuring that parts meet stringent engineering specifications. This technology minimizes material wastage and reduces labor costs, making it an essential asset for manufacturers focused on quality and productivity.

In the textile industry, cutting machines are essential for processing large volumes of fabric quickly and efficiently. Automated cutting systems can handle multiple layers of material, allowing for intricate patterns and designs to be produced in a fraction of the time it would take using manual methods. The application of laser cutting technology has also revolutionized textile production, providing precise cuts and the ability to create detailed designs without fraying edges. As a result, cutting machines have enabled manufacturers to bring innovative products to market faster while maintaining high standards of quality.

Cutting machines play a crucial role in the textile and apparel sector, enhancing efficiency and precision in fabric handling. These machines are designed to cut various materials into specific shapes and sizes, catering to diverse production needs. According to a report by the Technavio Research Group, the global cutting machine market in textile is expected to grow significantly, with a compound annual growth rate (CAGR) of around 6% from 2022 to 2026. This growth is driven by the increased demand for customized apparel and the necessity to streamline operations in garment manufacturing.

In textile production, cutting machines can be classified into various types, including manual, semi-automatic, and fully automatic systems. Automated cutting machines utilize advanced technology such as laser and digital cutting, which not only improve the accuracy of cuts but also minimize fabric waste. The National Textile Association reports that cutting machines can reduce fabric utilization rates by approximately 10-15%, translating into substantial cost savings for manufacturers.

As sustainability becomes a priority in the industry, the adoption of such cutting technologies reflects a pivotal shift towards more efficient resource management in textile manufacturing, ultimately benefiting both producers and consumers.

The cutting machine industry is on the brink of significant transformations driven by advancements in technology and automation. According to a report by MarketsandMarkets, the global cutting machine market is expected to reach USD 3.5 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.6% from 2021. Innovations in laser cutting, waterjet technology, and CNC (Computer Numerical Control) systems are paving the way for increased precision and efficiency across various sectors, including manufacturing, textiles, and metalworking.

Emerging trends highlight the integration of Artificial Intelligence (AI) and the Internet of Things (IoT) into cutting machine technology. These advancements enable machines to gather real-time data, leading to better maintenance schedules and predictive analytics that minimize downtime. A report from Grand View Research indicates that AI in manufacturing could drive productivity improvements by up to 30% by 2025. Additionally, sustainability concerns are pushing the industry towards more eco-friendly cutting practices, with a notable rise in demand for recyclable materials and energy-efficient machines. As these technologies evolve, they are not only enhancing operational efficiency but also redefining how cutting machines will function in tandem with future industry needs.