Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the competitive world of business, choosing the right tools is crucial. A Printing Machine Industrial can greatly enhance your production capabilities. These machines offer efficiency and quality that standard printing options often lack.

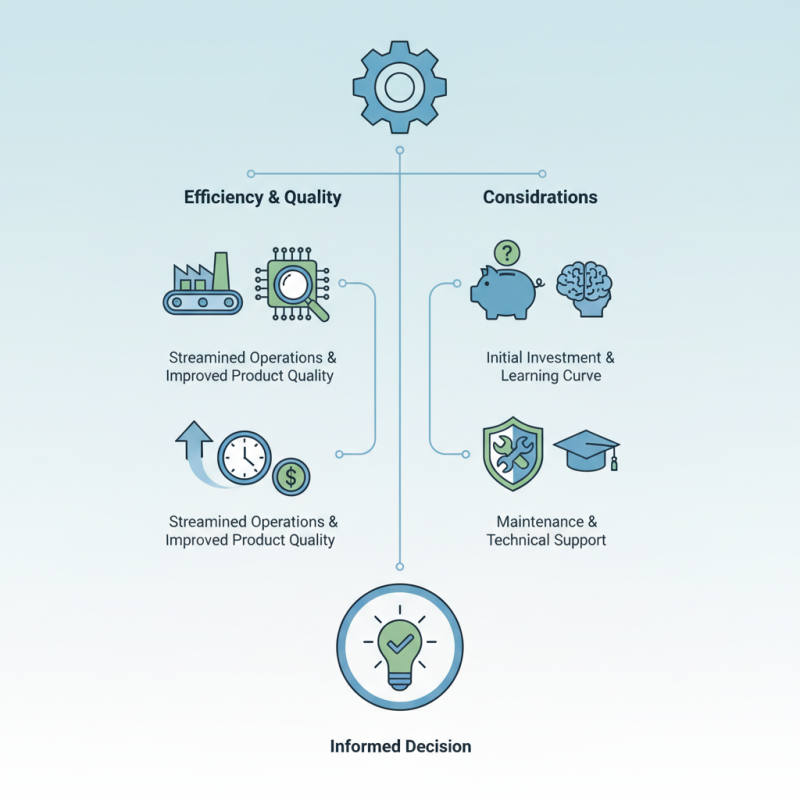

Investing in industrial printing machines is a decision that shouldn't be taken lightly. They can streamline operations and improve product quality. However, not every business fits the mold. Some may find the initial investment daunting. With so many options available, it’s essential to choose wisely.

Moreover, while industrial printing machines promise speed and efficiency, they come with a learning curve. Maintenance and technical support become significant factors. Ensuring that your team is well-trained can prevent costly errors. Reflecting on these points helps businesses make informed decisions that align with their goals.

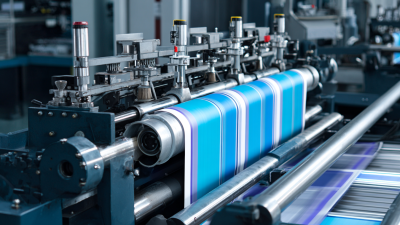

Industrial printing machines play a crucial role in modern manufacturing. They vary in types based on the specific needs of a business. Common types include flexographic, digital, and offset printing machines. Each type serves unique purposes. Flexographic machines excel in high-speed printing. They are ideal for packaging materials. Digital machines, on the other hand, offer flexibility and quick turnaround. They are perfect for short runs and custom jobs.

Offset printing machines stand out for their high-quality results. They are often used for large volume projects. Choosing the right machine depends on production needs. Evaluating cost, speed, and output quality is essential.

Many businesses overlook the maintenance required for these machines. Regular upkeep is necessary to avoid costly downtimes. Understanding the limitations and challenges of each type is vital. For instance, digital machines may struggle with very large formats. Organizations should weigh these considerations carefully before investing. Achieving the best results requires informed decisions and thoughtful planning.

Industrial printing machines offer significant advantages for businesses seeking efficiency and quality. According to a recent report by Smithers Pira, the global market for commercial printing is expected to reach $480 billion by 2025. This growth is driven by the need for high-quality outputs at lower costs. Using industrial printing can reduce material waste and save on production time.

One key advantage is the speed of production. Industrial machines can process large volumes quickly, meeting tight deadlines. A survey by Printing Industries of America found that 70% of companies reported increased productivity after switching to industrial printing equipment. With advanced technology, businesses can achieve consistent quality in every print.

Tip: Regular maintenance of printing machines keeps operations smooth. Ensure all parts are functioning well to avoid costly breakdowns.

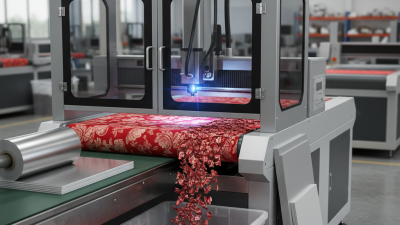

Flexibility is another essential factor. Industrial printers can handle various materials, from paper to fabric. However, one drawback is the initial investment cost. Businesses must weigh this against potential long-term savings. It's often a balancing act. Seeking industry recommendations and evaluating specific needs can help make this decision clearer.

Tip: Research the most used materials in your market to optimize the use of your printing machine. Understanding your target audience can guide your investments.

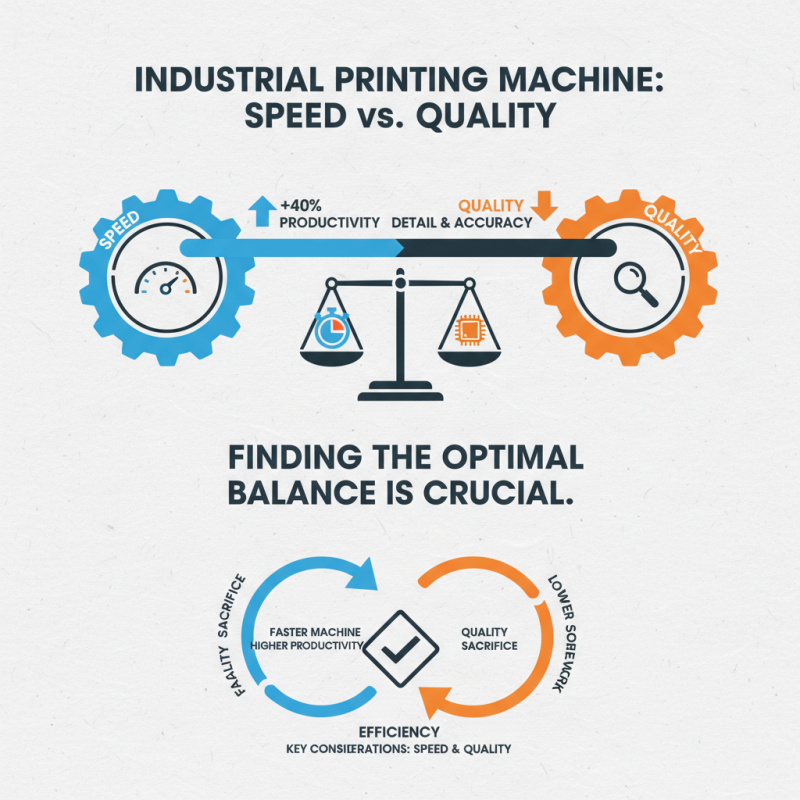

Choosing the right industrial printing machine is crucial for efficiency. Various factors come into play. One major consideration is the printing speed. Reports indicate that faster machines can increase productivity by up to 40%. However, if speed is prioritized, quality may suffer. Striking a balance is key.

Another factor is the type of materials used. Not all machines handle all substrates well. Some designs excel in printing on rigid materials, while others are better for flexible substrates. It’s essential to evaluate the specific needs of your business. It’s easy to overlook this detail, but improper material handling could lead to costly errors.

Lastly, consider maintenance costs. Industrial printers require regular servicing, which can add to overall expenses. Data shows that maintenance can account for 15% of operational costs. Companies often underestimate this factor. An initial low-price machine can become expensive over time due to high maintenance needs. Evaluating long-term costs is critical before making a decision.

Industrial printing machines can provide significant cost benefits to businesses. According to a recent industry report, companies that invest in advanced printing technology see a 30% reduction in production costs within the first year. This reduction is primarily due to improved efficiency and lower material waste. Additionally, customized printing solutions can help reduce time-to-market, which is crucial in today's competitive landscape.

Investing in industrial printers can also lead to increased revenue. A study shows that businesses using high-quality printing solutions can boost their sales by up to 25%. Customers often respond better to visually appealing products. The initial investment might seem daunting, but the long-term gains can justify the costs. It’s vital to assess your unique needs before making a decision.

Tip: Always conduct a thorough cost analysis. Evaluate maintenance costs, training costs, and material costs. Identifying hidden expenses can provide a clearer picture of overall savings.

Tip: Consider the scalability of the printing machine. As your business grows, your printing needs may evolve. Investing in scalable solutions can lead to better adaptability in the future. Regularly review your printing strategy. What works today may not be efficient tomorrow.

As industrial printing technology evolves, businesses must adapt to stay competitive. Future trends indicate a shift towards automation and sustainability. Companies that embrace these changes can streamline operations. They can save costs while improving product quality. However, not every company is ready for this transformation.

Investing in eco-friendly materials is a crucial trend. Sustainable printing practices can boost brand reputation. Customers today value environmentally conscious businesses. However, integrating green practices may require upfront investment. This can challenge some companies.

Tips for businesses include staying informed about new technologies. Regular training for staff can enhance efficiency. Consider collaborating with tech experts to explore new options. It's essential to reflect on current practices and identify areas for improvement. Small changes can lead to significant benefits over time.

| Dimension | Current State | Future Trends | Impact on Businesses |

|---|---|---|---|

| Print Speed | Up to 100 pages/min | Increased to 200 pages/min with enhancements | Higher productivity and reduced turnaround time |

| Print Quality | High resolution at 1200 DPI | Ultra HD quality (up to 4800 DPI) | Enhanced branding and product appeal |

| Ink Technology | Solvent and water-based inks | Eco-friendly, sustainable inks | Cost savings and improved environmental compliance |

| Customization Ability | Limited customization options | Fully customizable solutions | Increased market competitiveness and customer satisfaction |

| Cost Efficiency | High initial investment | Decreased operational costs | Higher profit margins and lower costs per unit |