Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

The industrial printing machine sector has experienced significant growth in recent years. According to a report by Smithers Pira, the market is expected to expand at a CAGR of 3.8% by 2025. This growth is driven by innovations in printing technology and rising demand for customized solutions across industries.

Expert Mark Johnson, a leading figure in industrial printing, emphasizes the impact of these machines: "Industrial printing machines are revolutionizing production lines with unmatched efficiency." As industries evolve, the necessity for high-quality, large-volume prints has never been more critical. Yet, the journey toward optimal printing solutions is not without its challenges. Companies often grapple with selecting the right equipment that balances cost and efficiency.

Understanding the top industrial printing machines can aid businesses in navigating this complex landscape. Companies must reflect on their specific needs and how emerging technologies can meet them. The effectiveness of industrial printing machines will largely depend on a company’s ability to adapt and innovate in an increasingly competitive market.

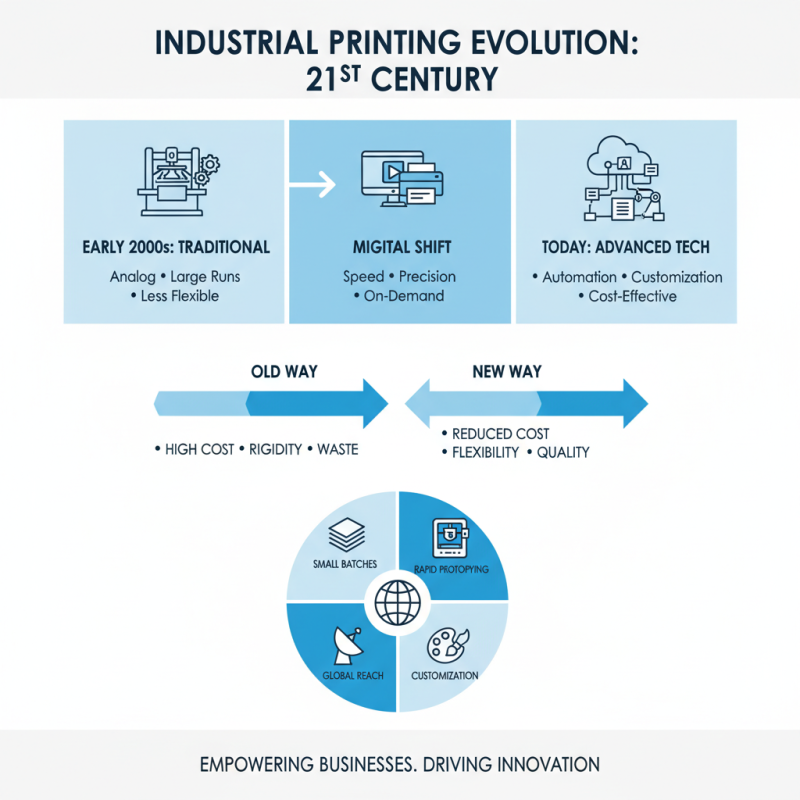

The evolution of industrial printing machines in the 21st century has been remarkable. Traditional printing methods are giving way to advanced technologies. Digital printing has transformed industries by offering speed and precision. No longer are large print runs required, allowing for more flexibility. This shift has empowered companies of all sizes to produce high-quality prints at a reduced cost.

Moreover, innovations like 3D printing are gaining traction. They redefine how products are manufactured. Designers now turn ideas into tangible items rapidly. However, not every venture into modern printing technology is smooth. Issues with material compatibility and machine maintenance still arise. Companies must balance cost with performance to choose the right solutions.

Sustainability has also become crucial. Many machines now focus on reducing waste and energy consumption. Yet, the transition can be challenging. Older machines often remain in operation, complicating the shift to greener technologies. The journey toward a fully digital and sustainable printing world is ongoing, filled with both opportunities and hurdles.

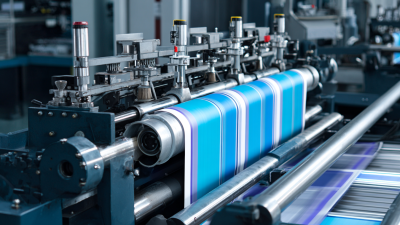

When exploring industrial printing technologies, there are several key types to consider: inkjet, laser, and more. Inkjet printing excels in producing high-quality images. This technology sprays tiny droplets of ink onto the printing surface. It is great for photo printing and creating vibrant graphics. Yet, it can struggle with speed in larger jobs. There’s a learning curve involved too, especially when aiming for consistent quality.

Laser printing, on the other hand, uses a different approach. It employs lasers to fuse toner onto the paper. This method is typically faster than inkjet printing. It’s ideal for high-volume tasks. However, the initial setup can be complex. Users may face challenges in maintenance as the machine requires regular upkeep. The differences between these technologies highlight the need for proper selection based on specific needs.

In addition to these, there are other specialized methods. Technologies like thermal and UV printing cater to unique applications. They each come with their own set of advantages and drawbacks. Sometimes, the latest gadget isn't the best fit. Evaluating specific requirements is crucial to avoid costly mistakes.

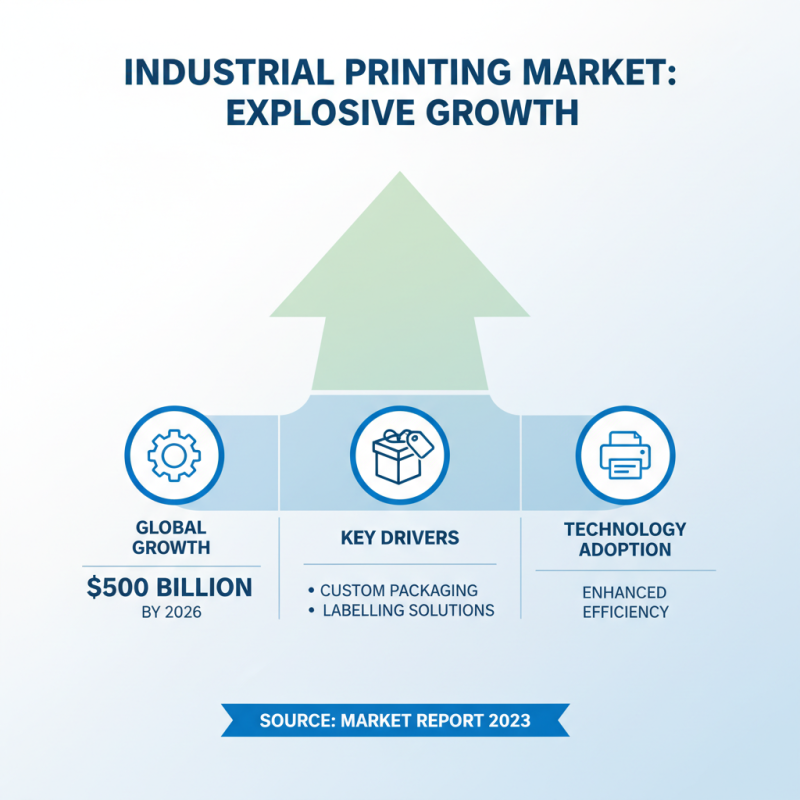

The global industrial printing industry is witnessing significant growth. According to a recent market report, the industry is projected to reach a value of over $500 billion by 2026. This growth can be attributed to the increasing demand for customized packaging and labeling solutions. Industries are embracing new printing technologies, leading to enhanced efficiency.

In recent years, digital printing has gained traction. Its ability to produce high-quality prints at lower costs is appealing to many manufacturers. A study shows that digital printing will account for more than 30% of the market share by the end of 2025. Companies are investing heavily in this technology. However, this transition can be challenging, as many businesses struggle to adapt their traditional practices.

Tips: Keep an eye on emerging printing trends. Understanding these developments can help businesses stay competitive. Regularly evaluate your printing technologies to ensure they meet current demands. The landscape is changing quickly. Explore different printing options to find what suits your needs best.

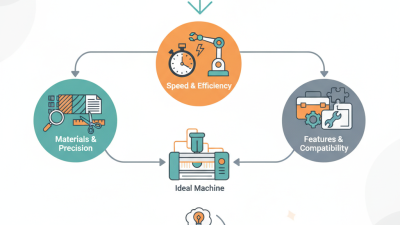

When selecting an industrial printing machine, several features demand your attention. Print speed is crucial. A faster machine boosts productivity, saving time and resources. Quality should not be sacrificed. Look for machines that provide sharp, vibrant prints. Resolution is key. Machines with higher DPI (dots per inch) often yield better results, especially for detailed work.

Consider the material compatibility. Some machines handle diverse substrates well, while others are limited. Assess your specific needs and choose accordingly. Ease of use is important too. Look for intuitive interfaces. A complex machine can lead to errors and frustration, impacting workflow.

Additionally, maintenance is a critical point. Some machines require regular upkeep, while others are low-maintenance. Evaluate your capacity for downtime. Finally, budget is always a concern. Balancing cost with features can be tricky. It will require some contemplation and adjustment. Choose wisely to avoid future regrets.

| Machine Type | Max Print Speed (IPM) | Print Resolution (dpi) | Print Width (inches) | Connectivity | Key Features |

|---|---|---|---|---|---|

| Digital Inkjet | 300 | 1200 x 1200 | 54 | USB, Ethernet | High quality, Versatile media handling |

| UV Flatbed | 100 | 1440 x 1440 | 62 | Wi-Fi, USB | Prints on various substrates, Fast curing |

| Label Printer | 150 | 600 x 1200 | 8 | Ethernet, Serial | Compact design, High-speed printing |

| 3D Printer | 40 | N/A | 10 | USB, Wi-Fi | Flexible materials, Prototyping |

| Flexo Printer | 200 | 800 x 800 | 30 | Remote access | Cost-effective, Large print runs |

| Screen Printer | 80 | 600 x 600 | 24 | Manual, Semi-automatic | High opacity inks, Suitable for textiles |

| Sublimation Printer | 90 | 1200 x 1200 | 44 | Wi-Fi, Ethernet | Vivid colors, Excellent for textiles |

| Laser Printer | 150 | 1200 x 2400 | 12 | USB, Network | Fast print speed, High-quality text |

| Wide Format Printer | 60 | 2400 x 1200 | 61 | USB, Ethernet | Large format capability, Ideal for banners |

| Dot Matrix Printer | 200 | 300 x 300 | 9 | Serial, USB | Durable, Continuous printing |

The industrial printing sector has witnessed remarkable transformations through successful case studies. One notable example is a packaging firm that adopted advanced digital printing techniques. Within six months, their production speed increased by 40%. This shift enabled them to respond quickly to market demands. However, they encountered challenges in transitioning staff to the new technology. Training programs were essential but costly.

Another success story comes from a textiles company that integrated large-format printers into their operations. The result was a 30% reduction in waste. They were able to print directly onto fabrics, eliminating several steps in the production line. Despite the clear benefits, they struggled with setup times, which delayed job starts. Their experience highlights the importance of ongoing optimization.

Data from a recent industry report indicates that the global industrial printing market is expected to reach $20 billion by 2025. This growth underscores the need for companies to embrace innovation while addressing human factors in technology adoption. Success is not just about machines; it’s about people and processes.