Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

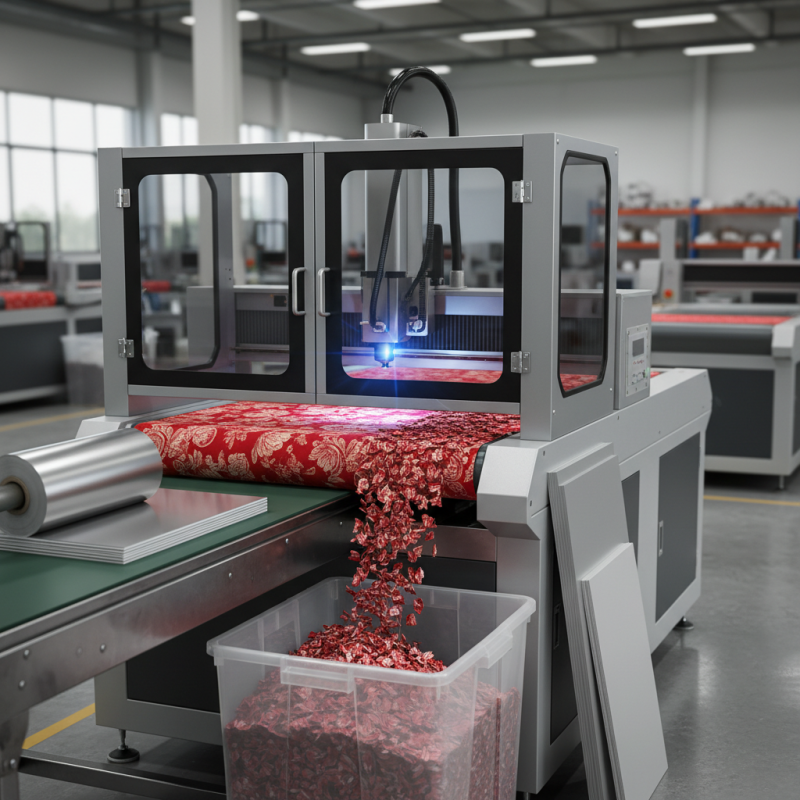

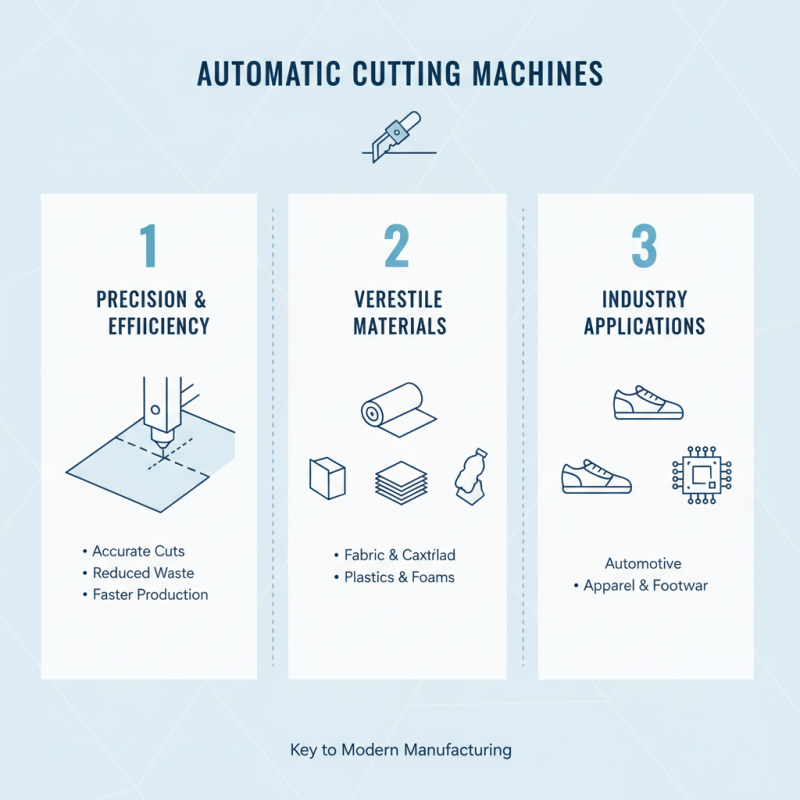

An Automatic Cutting Machine is a revolutionary tool in modern manufacturing. It streamlines the cutting process, enhancing efficiency and precision. Instead of manual methods, these machines utilize advanced technology to cut materials like fabric, metal, and plastic. They can operate with minimal human intervention, saving time and labor costs.

These machines function using various techniques, including laser cutting, rotary cutting, and knife cutting. Each method offers distinct advantages. For instance, laser cutting provides clean edges and intricate designs. Yet, it may not be suitable for all materials. Understanding these details is crucial for selecting the right machine for your needs.

While Automatic Cutting Machines boast notable benefits, they are not without challenges. Maintenance is essential to ensure optimal performance. Additionally, the initial investment can be substantial. Choosing the right machine requires careful consideration. Not every business may find it a perfect fit, and that’s worth reflecting on.

An automatic cutting machine is a device designed for precision cutting in various industries. It efficiently processes materials such as fabric, paper, and plastics. These machines use computer-controlled settings to achieve consistent and accurate cuts. The level of detail they provide can be impressive, which enhances production efficiency.

The operation of an automatic cutting machine involves software that takes input designs and translates them into machine movements. Users can input various dimensions and shapes, and the machine executes the design. However, it's essential to ensure that the input data is correct. Inaccurate data can lead to miscuts, resulting in wasted materials. This aspect requires careful attention.

While automatic cutting machines can significantly improve productivity, they also have drawbacks. Training is necessary to operate them effectively. Not all workers adapt quickly. Additionally, maintenance is crucial to keep the machinery in good working condition. Neglecting this can lead to machinery breakdowns and unexpected costs. These are factors that require careful consideration when integrating automatic cutting technology into a workflow.

Automatic cutting machines are advanced tools used in various industries. They offer precision and efficiency in cutting materials like fabric, paper, and plastic. These machines are heavily relied upon in manufacturing processes where speed is crucial.

Key components of these machines include blades, controllers, and frames. Blades are designed to handle different materials. They need regular maintenance for optimal performance. Controllers manage the cutting process and can be programmed for various tasks. Frames provide stability and support, allowing the machine to operate smoothly.

Despite their efficiency, automatic cutting machines can pose challenges. Misalignment can lead to waste. Users must stay vigilant to avoid costly mistakes. Proper training is crucial to operate these machines safely. The technology is advancing, but humans still play a vital role in the quality assurance process.

Automatic cutting machines revolutionize manufacturing. They can handle various materials, including fabric, metal, and plastic. These machines use advanced technology to cut shapes with precision. This capability enhances production efficiency significantly.

In a busy workshop, every second counts. Traditional cutting methods often take time and involve human error. An automatic cutting machine reduces these risks. Operators can input designs, and the machine does the rest. This allows for faster turnaround times and less waste. However, it requires skilled personnel to oversee the process. Monitoring and maintenance are crucial for optimal performance.

Still, challenges persist. Not all materials can be cut with equal efficiency. Some may require different settings or tools. Workers must constantly adapt. Misalignment issues can also occur. This highlights the need for ongoing training and vigilance. Even with the benefits, finding the right machine for specific tasks requires careful consideration.

Automatic cutting machines play a vital role in various industries today. These machines increase efficiency and reduce material waste. They work by using advanced technology to cut materials with high precision. Industries like textiles, woodworking, and packaging rely on these machines to maintain production speed and quality.

In the textile industry, automatic cutting machines streamline the process of cutting fabrics. They eliminate the need for manual cutting, which can be inconsistent. However, errors can occur if the machine settings are miscalibrated. This can lead to wasted materials and added costs. In woodworking, these machines help create intricate designs with accurate cuts, saving time and labor. Still, operators must regularly check the machine's alignment to ensure quality.

The packaging sector also benefits from automatic cutting machines. They create custom packaging sizes and shapes efficiently. Despite their advantages, over-reliance on these machines can create challenges. If a machine breaks down, it can halt production lines. It's crucial to balance automation with skilled labor to maintain control over the process. Regular training for staff can help mitigate potential issues and keep production running smoothly.

This chart illustrates the market share distribution of automatic cutting machines across various industries. The textile and plastics sectors dominate the market, highlighting the versatility and demand for cutting solutions in diverse applications.

The future of automatic cutting machine technology promises significant advancements. As industries strive for efficiency, these machines are evolving. Research indicates the global automatic cutting machine market will reach $6.1 billion by 2027, growing at a CAGR of 6.5%. This growth is driven by increasing automation in manufacturing.

One key trend is the integration of AI and machine learning. These technologies enhance precision and reduce waste. Machines can now learn from previous cuts, adapting to different materials and minimizing errors. For instance, inaccurate cuts in the automotive sector can lead to costly rework. The ability to predict and rectify mistakes before they happen is invaluable.

However, this shift requires careful consideration. The initial investment in advanced machines can be significant. Small manufacturers may struggle to adopt these innovations. Additionally, workforce training remains a challenge. Skilled operators are essential for maximizing machine potential. Balancing technology with human expertise will be crucial moving forward. The journey of innovation involves both opportunities and hurdles, and reflection on these aspects is necessary.