Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

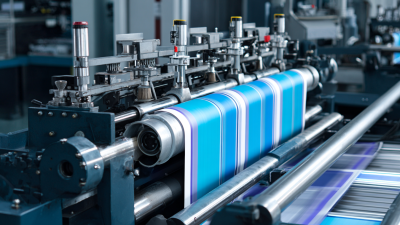

In the ever-evolving landscape of manufacturing and crafting, selecting the right equipment can significantly influence your production efficiency and product quality. As we approach 2025, one critical tool that stands at the forefront of this evolution is the stamping machine. Whether you are a small business owner, a hobbyist, or an industrial manufacturer, understanding how to choose the best stamping machine tailored to your specific needs is essential for optimizing your workflow.

This guide aims to equip you with the necessary insights and considerations to navigate the diverse range of stamping machines available on the market. From evaluating the size and power of the machine to understanding the types of materials you will be working with, we will delve into the key factors that will help you make an informed decision. Additionally, we will explore the latest technological advancements that are shaping the future of stamping machines, ensuring that you are not only well-prepared for today's demands but also poised for tomorrow's challenges. Whether you're aiming to enhance productivity or achieve intricate designs, the right stamping machine will play a pivotal role in your success.

When selecting a stamping machine, it's essential to prioritize key features that cater to your specific needs. According to a report by IBISWorld, the market for stamping machines has seen a significant growth rate of 5.2% annually, emphasizing the importance of investing in advanced technology. One primary feature to consider is the machine's capacity, which determines the maximum size and thickness of materials it can handle.

For example, high-capacity stamping machines can efficiently work with heavier materials, making them ideal for high-volume industrial applications.

Another crucial aspect is the type of drive system utilized in the machine. Mechanical, hydraulic, and servo-driven systems each offer different advantages. A 2023 study by Grand View Research highlighted that servo-driven stamping machines have gained popularity due to their energy efficiency and precision, reducing operational costs by up to 25%. Additionally, consider the level of automation available, as fully automated machines can significantly increase productivity while minimizing labor costs.

Investing time in evaluating these features ensures you choose a stamping machine that aligns with your production goals and operational efficiency.

In 2025, identifying the best stamping machine for your needs requires a thorough comparative analysis of the top contenders in the market. The global CNC machine market, which encompasses stamping machines, is projected to grow significantly, from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, showcasing a compound annual growth rate (CAGR) of 9.9%. This growth trend indicates that manufacturers are continuously evolving and innovating their technologies to meet varying production demands.

When selecting the ideal stamping machine, it is crucial to consider key factors such as precision, production speed, and operational versatility. Among the top five stamping machines of 2025, models are equipped with advanced features that enhance productivity and minimize waste. By analyzing specifications and user reviews, potential buyers can better understand which machine aligns with their operational requirements. With the rapid advancements in CNC technology, investing in a high-quality stamping machine is vital for businesses aiming to stay competitive in an expanding market.

When choosing the best stamping machine for your needs, understanding your specific stamping requirements is crucial. Different industries have varied applications; for instance, automotive stamping requires high precision and robust durability, while the electronics sector may prioritize speed and flexibility. According to a recent report by MarketsandMarkets, the global stamping equipment market is projected to reach $16 billion by 2025, highlighting the rising demand for advanced stamping technologies across various sectors.

Tip 1: Assess the materials you will be working with. Machines designed for softer metals differ significantly from those suited for tougher materials like stainless steel. This understanding will guide you toward the right machine that aligns with your operational capabilities.

Tip 1: Assess the materials you will be working with. Machines designed for softer metals differ significantly from those suited for tougher materials like stainless steel. This understanding will guide you toward the right machine that aligns with your operational capabilities.

Consider the scale of production as well. A batch production system may require a different stamping machine configuration compared to a high-volume manufacturing setup. The same MarketsandMarkets report indicates that the demand for automated stamping machines is increasing, primarily due to the efficiency they bring to high-output environments.

Tip 2: Evaluate the machine’s capability for customization. As industries evolve, having a stamping machine that can adapt to different formats and materials will save costs and downtime in the long run. Understanding these needs will allow you to make a well-informed investment.

When looking for the best stamping machine, understanding the balance between price and performance is essential. A higher price does not always guarantee superior performance; therefore, it's crucial to evaluate the specific requirements of your projects. For small businesses or hobbyists, an entry-level machine that offers solid capabilities at a reasonable price point can be a great choice. In contrast, larger enterprises might need a more advanced, robust machine that can handle high volumes and complex tasks, making the investment worthwhile.

**Tip 1:** Before purchasing, assess the types of materials and the volume of production you’ll be working with. This will help you determine the necessary features and avoid overpaying for functionalities you may not need.

When it comes to value, consider the long-term costs associated with each option. Cheap machines may save you money upfront but could lead to higher maintenance costs or replacement needs in the future. Investing in a machine known for its durability and low maintenance can be more economical in the long run.

**Tip 2:** Read customer reviews and seek recommendations from industry professionals to gauge the reliability and performance of various models. This firsthand knowledge can significantly influence your decision-making process.

When selecting a stamping machine for your business, maintenance and support should be at the forefront of your evaluation process. According to a report from MarketsandMarkets, the global stamping machine market is expected to grow from USD 24.3 billion in 2020 to USD 32.5 billion by 2025, driven largely by advancements in technology and increasing demand for automation. However, the acquisition of such technology also entails a long-term commitment to maintenance and support, which can significantly affect operational efficiency and costs.

Evaluating the manufacturer’s support services is crucial. A study by the International Society of Automation found that effective preventive maintenance can increase equipment lifespan by 30% and reduce downtime by 20%. When considering potential suppliers, look for those that offer comprehensive service agreements, prompt customer support, and accessible spare parts. This will ensure that your stamping machine remains operational and efficient, minimizing unexpected expenses and maximizing productivity as you adapt to evolving production needs.