Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

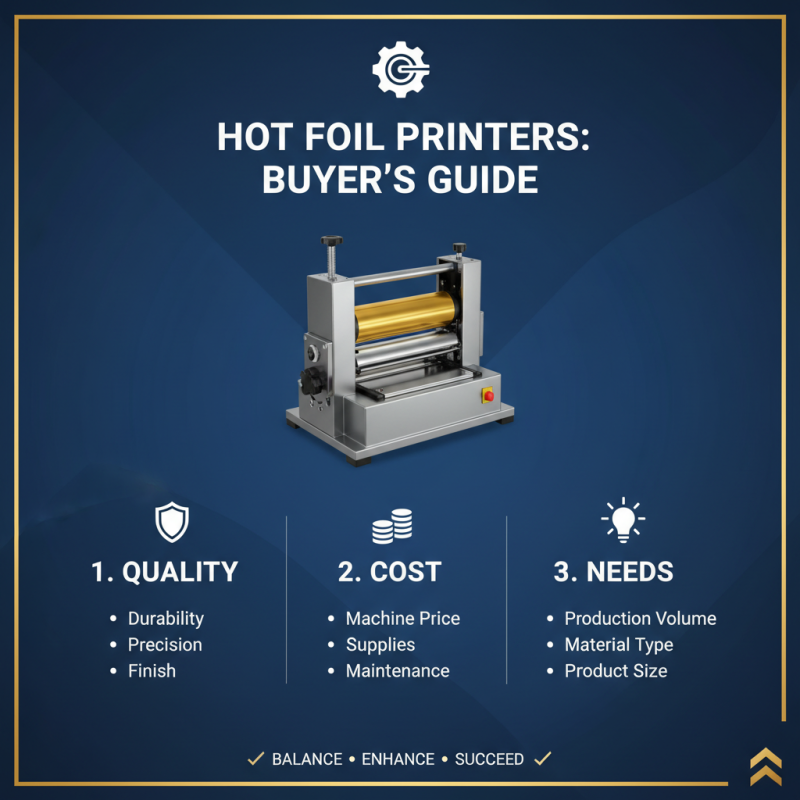

In today's competitive market, choosing the right Hot Foil Printing Machine can make a significant difference in your business. These machines offer versatility and creativity, allowing companies to produce stunning foil effects on various materials. Their potential can elevate products, making them stand out. However, with so many options available, selecting the ideal machine can be overwhelming.

The effectiveness of a Hot Foil Printing Machine greatly depends on your specific needs. Different machines come with various features and capabilities. Some may excel in high-volume production, while others offer intricate detail for smaller projects. Think about what your business requires. Consider the range of products you want to enhance.

It's essential to reflect on the long-term investment of a Hot Foil Printing Machine. Not all machines will deliver satisfactory results. Some may not withstand heavy use, while others may lack reliability. Evaluating your choices carefully can prevent future regrets. Take time to explore the options available and make an informed decision.

Hot foil printing is a fascinating technique that adds metallic finishes to various materials. It combines heat and pressure to transfer foil onto surfaces. This method creates vibrant designs and luxurious textures. Businesses in packaging, stationery, and crafts often use this process. The visual appeal is undeniable, making products stand out on shelves.

However, mastering hot foil printing isn't always straightforward. Finding the right machine can be a challenge. Costs can vary widely, impacting business decisions. Operators must also consider maintenance and the learning curve involved. An imperfect print could ruin an otherwise great design. It's essential to experiment with different setups and foils for the best results.

Additionally, understanding the material's compatibility is crucial. Some substrates respond better to foil than others. It's necessary to test and refine approaches. Each project may require adjustments and creativity. The balance between cost and quality is vital. Investing time in skill development can lead to better outcomes. Embracing the imperfections might eventually lead to innovative techniques and unique products.

When selecting a hot foil printing machine, several key features can greatly impact your business’s success. First, consider the machine’s temperature control. Precise temperature regulation ensures optimal foil adhesion. According to industry reports, machines with adjustable temperature settings increase accuracy by up to 30%. This can lead to reduced waste and improved print quality.

Next, evaluate the speed of the machine. High-speed machines can handle large volumes efficiently, enhancing productivity. A study revealed that businesses utilizing faster machines saw a 40% rise in output. This is especially vital during peak seasons. Quality should not be sacrificed for speed, though. Look for machines that balance both aspects.

Tips: Always test a machine’s ease of use. Complex setups can slow down production, especially for new operators. Additionally, assess the machine's compatibility with various foils and substrates. Not all machines work well with every foil type, leading to unsatisfactory results. Investing time upfront in thorough research can save significant frustration later.

| Machine Model | Max Paper Size (inches) | Foil Width (inches) | Speed (impressions/hour) | Heat Type | Digital Control |

|---|---|---|---|---|---|

| Model A | 12 x 18 | 6 | 1000 | Electric | Yes |

| Model B | 10 x 14 | 5 | 800 | Gas | No |

| Model C | 15 x 22 | 7 | 1200 | Electric | Yes |

| Model D | 11 x 17 | 4 | 900 | Gas | No |

| Model E | 16 x 24 | 8 | 1500 | Electric | Yes |

| Model F | 14 x 20 | 6 | 1100 | Gas | No |

| Model G | 12 x 18 | 5 | 950 | Electric | Yes |

| Model H | 10 x 14 | 4 | 750 | Gas | No |

| Model I | 15 x 22 | 6 | 1300 | Electric | Yes |

| Model J | 11 x 17 | 5 | 1000 | Gas | No |

When considering hot foil printing machines, choosing the right one is crucial. The market offers various options, each with unique features. You'll want a machine that balances quality and price while meeting your business needs. The right machine can enhance your production and improve your final product.

While selecting a machine, focus on its capabilities. Some machines handle thicker materials better. Others may feature adjustable heat settings. Consider how often you plan to use it. Frequent usage may require a more robust model. Don’t overlook the importance of customer reviews. They can offer valuable insights into performance and reliability.

Tips for your purchase: Always check the warranty terms. A longer warranty can mean better durability. Also, think about the size and space in your workspace. If space is a constraint, smaller machines may be more suitable. Finally, test the machine before committing. This step can help ensure it meets your expectations. Buying blindly can lead to regret.

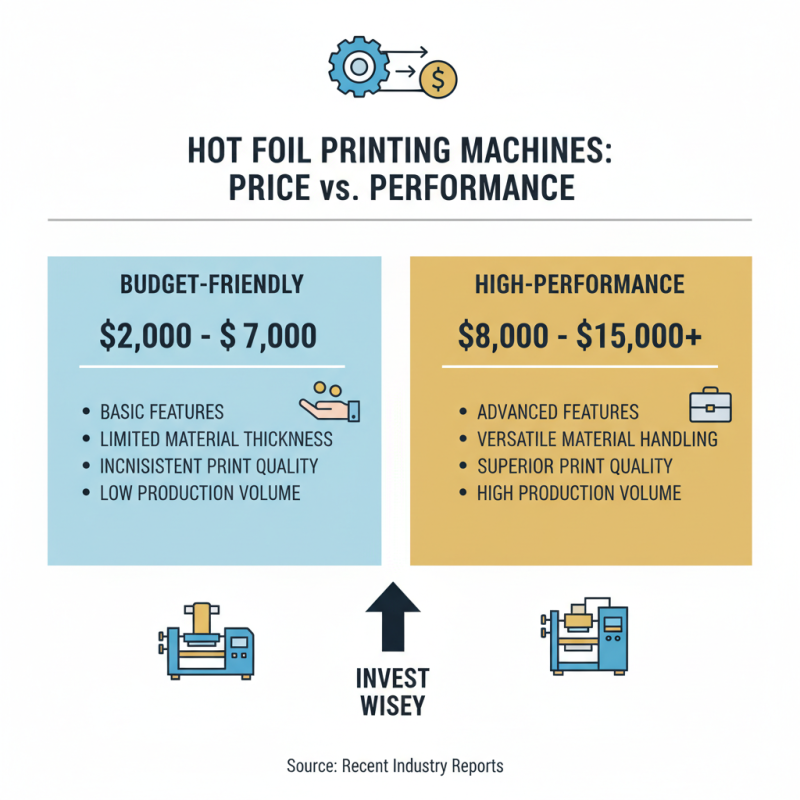

When selecting a hot foil printing machine, it's crucial to analyze both price and performance. Recent industry reports highlight that the price range for quality machines can vary significantly, from $2,000 to over $15,000. A detailed evaluation reveals that machines in the lower price bracket often lack advanced features. They may struggle with thicker materials, leading to inconsistent print quality. Invest wisely based on your expected production volume.

Performance indicators are equally important. Speed, precision, and versatility shape the functionality of these machines. For instance, reports indicate that a high-performance model can achieve up to 1200 impressions per hour. In contrast, entry-level models may only manage 500, making them less suitable for larger projects. It's essential to weigh these factors against the costs. A more expensive model might yield lower long-term operational costs despite the higher upfront investment.

Finally, maintenance and operational costs can affect long-term value. Machines require regular upkeep to sustain performance. An inexpensive machine might seem appealing initially, but repairs can quickly accumulate. Balancing initial investment and operational longevity is vital. This approach ensures that your choice aligns with your business's unique needs and production goals.

Maintaining foil printing machines is crucial for their performance and longevity. Regular maintenance can prevent costly breakdowns. According to a recent industry report, poorly maintained machines can reduce productivity by up to 30%. Cleaning the rollers and heaters often can help avoid issues caused by dust and adhesive buildup. Some operators overlook this simple task, which can lead to uneven prints and increased waste.

Temperature control is another vital aspect. Foil printing requires specific heat settings for optimal results. A recent study indicated that operating outside recommended temperatures could decrease the foil’s adherence by approximately 15%. Many operators do not regularly check these settings, leading to inconsistent quality in their prints. Ignoring these details can cost businesses time and materials.

Lubrication of moving parts is essential for smooth operation. According to maintenance best practices, failing to lubricate can lead to friction and wear, potentially shortening the machine's lifespan. Operators often skip this step due to time constraints. However, it is critical for maximizing efficiency and avoiding unexpected downtimes. Regular inspections and following a maintenance checklist can drastically enhance performance and extend the machine's life.