Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the world of crafting, the right tools can make all the difference in transforming an average project into a dazzling masterpiece. Among these essential tools, a Foil Press Machine stands out as a game-changer for avid crafters and hobbyists alike. By enabling the application of metallic foils to a variety of surfaces, these machines add an eye-catching touch to cards, invitations, and personalized gifts. As crafting continues to grow in popularity, understanding the features and benefits of foil press machines becomes crucial for elevating your creative endeavors.

This article delves into the top 10 foil press machines that can enhance your crafting projects, regardless of your skill level. From intricate designs to bold statements, a quality foil press machine can help you unlock new possibilities in your artistic expression. We will explore the key features, ease of use, and versatility of each machine, ensuring you have all the information you need to make an informed choice tailored to your crafting style. Whether you're a seasoned professional or just starting out, incorporating a foil press machine into your toolkit can significantly elevate your projects, infusing them with a touch of elegance that is sure to impress.

When it comes to enhancing your crafting projects, a quality foil press machine can make all the difference. These machines come equipped with a range of features designed to help crafters achieve stunning results with ease. Key features often include adjustable temperature settings, which allow for precise control over the foiling process, ensuring that designs adhere effectively to various materials. Additionally, many models offer a variety of pressure settings, enabling users to work with different types of foiling sheets and substrates without compromising on quality.

Beyond technical specifications, the benefits of using a foil press machine are substantial. One major advantage is the ability to create professional-looking foil accents on greeting cards, invitations, and other paper crafts. The instant gratification of achieving beautiful, shiny results can significantly enhance both the aesthetic appeal and perceived value of crafted items. Furthermore, many machines boast user-friendly interfaces that simplify operation, making them accessible for crafters of all skill levels. With the right foil press machine, crafters can unlock limitless creative possibilities, transforming ordinary projects into extraordinary pieces of art.

The crafting industry has witnessed remarkable growth in recent years, an evolution prominently driven by advancements in foil pressing technologies. According to a report by ResearchAndMarkets, the global crafting market is projected to reach $50 billion by 2025, with a significant boost from innovations that enhance the crafting experience. Crafting is no longer just a niche hobby; it has become a lucrative market with a diverse range of enthusiasts, from DIY aficionados to professional artisans.

Foil press machines, in particular, have revolutionized the way creators apply designs and embellishments, adding a professional touch to homemade projects. The appeal of these machines lies in their ability to produce intricate designs that were once reserved for commercial production. A market analysis by Technavio highlights that the demand for foil stamping equipment is expected to grow at a CAGR of 7% between 2021 and 2025, reflecting the rising popularity of personalized and customized craft items. This trend is shaping not only individual creativity but also influencing retail strategies as more craft suppliers cater to consumer demands for high-quality crafting tools.

As the trend towards personalization continues to gain momentum, the integration of advanced technologies in crafting, particularly in foil pressing, showcases the industry’s adaptability. Craft enthusiasts are increasingly seeking tools that enhance their creative processes, driving manufacturers to innovate and diversify their product lines. With the growing emphasis on accessibility and efficiency in crafting technologies, the future looks promising for both novice and experienced crafters alike.

| Model Name | Heat Up Time (minutes) | Max Foil Width (inches) | Pressure Settings | Weight (lbs) | Price ($) |

|---|---|---|---|---|---|

| Model A | 5 | 12 | 3 | 8 | 199.99 |

| Model B | 3 | 10 | 4 | 7 | 149.99 |

| Model C | 6 | 14 | 2 | 9 | 279.99 |

| Model D | 4 | 12 | 5 | 10 | 229.99 |

| Model E | 7 | 15 | 3 | 8.5 | 299.99 |

| Model F | 2 | 8 | 4 | 6 | 119.99 |

| Model G | 5 | 10 | 3 | 7 | 199.99 |

| Model H | 6 | 14 | 2 | 9.5 | 249.99 |

| Model I | 4 | 12 | 5 | 10.5 | 219.99 |

| Model J | 3 | 10 | 4 | 8 | 169.99 |

When selecting a foil press machine, it’s essential to consider both price ranges and performance metrics to ensure that your investment delivers the best results for your crafting projects. Prices can vary significantly, from budget-friendly options suitable for beginners to high-end machines that offer advanced features for professional crafters. Understanding what you’re willing to spend can help narrow down choices and ensure that you pick a machine that meets your needs while still being accessible.

Performance metrics such as heating time, temperature control, and ease of use are crucial for achieving optimal results in foil pressing. Machines that heat up quickly and maintain a consistent temperature can significantly improve efficiency. Additionally, user-friendly designs that incorporate intuitive controls can enhance your crafting experience, reducing frustration and allowing you to focus on your creative endeavors.

**Tips:** Before making a purchase, consider what types of projects you plan to undertake. If you envision large-scale work, investing in a robust machine might be wise, but for smaller, occasional crafts, a more economical option could be sufficient. Always check for customer reviews and performance ratings to gauge how well a machine performs in real-world applications.

When selecting a foil press machine, user experiences play a crucial role in discerning the best options available on the market. Many crafters praise machines that offer intuitive controls, seamless operation, and consistent results. The feedback often highlights the importance of user-friendliness, as novice and seasoned creators alike seek machines that simplify the crafting process while offering professional-quality results. Customers have shared their satisfaction with models that feature adjustable temperature settings and quick heat-up times, which contribute to a more efficient crafting experience.

Additionally, reviews frequently mention the versatility of foil press machines in enhancing various projects, from card making to home decor. Users appreciate machines that are compatible with different materials and foil types, enabling them to experiment and innovate with their designs. The durability and build quality of these machines also emerge as key factors, with users reporting long-lasting performance, which ultimately justifies their investment. Overall, the collective feedback reflects a significant desire for machines that combine functionality, ease of use, and versatility, enabling crafters to elevate their projects effectively.

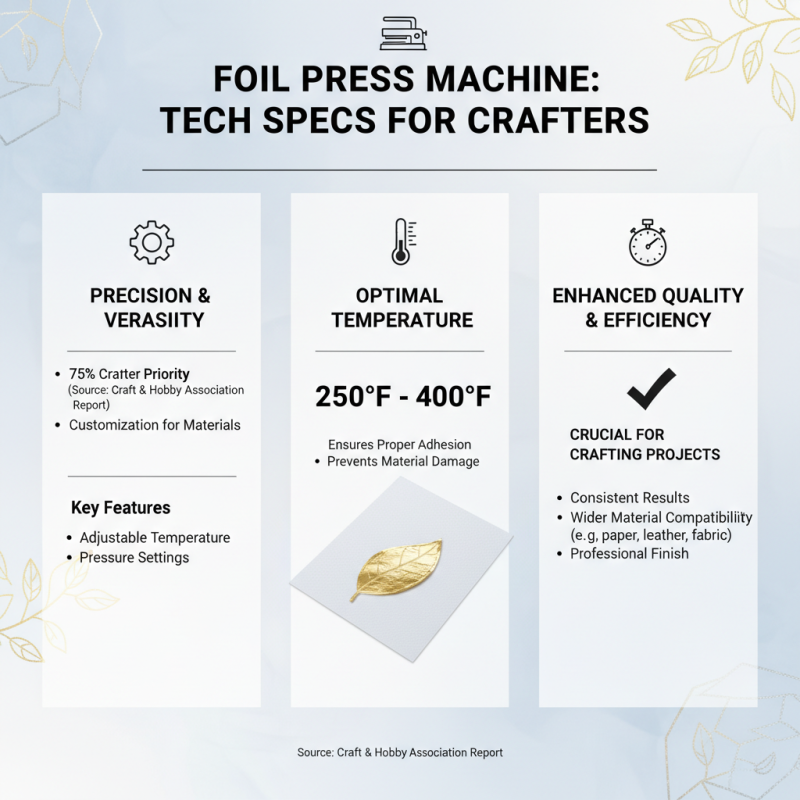

When selecting a foil press machine for your crafting projects, understanding the technical specifications is crucial for enhancing the quality and efficiency of your work. A report by the Craft and Hobby Association indicates that nearly 75% of crafters prioritize precision and versatility in their tools. Features such as adjustable temperature controls and pressure settings are essential; they allow creators to customize their projects according to different materials. For example, optimal temperature ranges for foil application typically lie between 250°F and 400°F, ensuring the foil adheres properly without damaging the underlying substrate.

In addition, the size and type of heating plate significantly impact the machine’s usability. A larger heating plate means more extensive designs can be achieved in a single application, reducing setup time and increasing productivity. Craft industry insights reveal that machines equipped with silicone mats can improve foil transfer efficiency and reduce the risk of warping. Furthermore, user-friendly interfaces with digital displays simplify navigation through settings, making it easier for crafters of all skill levels to achieve professional results. Investing in a foil press machine with these essential features not only enhances project outcomes but also elevates the overall crafting experience.