Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the manufacturing industry, precision and efficiency are paramount, and at the heart of many production processes lies the Stamping Machine. Designed to create intricate shapes and components from metal sheets, these machines have evolved significantly over the years, incorporating advanced technology to improve their performance and output. As we step into 2023, it is crucial for manufacturers to be equipped with machinery that not only meets their production needs but also enhances the accuracy of their work.

This guide explores the top 10 stamping machines available in 2023, highlighting their key features that contribute to precision and overall efficiency. From state-of-the-art automation capabilities to enhanced sensitivity that ensures uniformity in production, these machines represent the latest advancements in the stamping domain. Selecting the right stamping machine can greatly impact productivity, reduce material waste, and ultimately lead to higher quality products. Join us as we delve into the leading options that are setting new standards in the industry.

Stamping machines play a crucial role in various industries, particularly in manufacturing, automotive, and electronics. Their ability to precisely shape metal and other materials makes them invaluable in producing parts for numerous applications. According to a report by Research and Markets, the global stamping market is expected to reach $330 billion by 2027, driven by the increasing demand from sectors such as automotive, where components like chassis and body parts require high precision and efficiency. The evolution of technology in stamping machines has also enhanced their capabilities, allowing for faster production rates without compromising on quality.

The applications of stamping machines extend beyond merely forming shapes; they assist in processes such as blanking, punching, and embossing. In the automotive industry, for instance, advanced stamping technology ensures that components meet stringent safety and performance standards. Similarly, in electronics manufacturing, precision stamping is critical for the fabrication of small components that must fit within tightly specified tolerances. A report by MarketsandMarkets highlights that continuous advancements in automation and robotics in stamping processes are projected to improve operational efficiency by up to 30% over the next few years. These innovations are essential for manufacturers aiming to stay competitive in a fast-paced market and meet increasing consumer demands.

| Machine Model | Max Stroke (mm) | Accuracy (mm) | Production Speed (strokes/min) | Applications |

|---|---|---|---|---|

| Precision Stamping 3000 | 150 | 0.01 | 600 | Automotive parts |

| Precision Stamping Pro | 200 | 0.005 | 800 | Electronics |

| High-Speed Stamping 500 | 120 | 0.02 | 1000 | Medical devices |

| Compact Stamping Unit | 90 | 0.015 | 500 | Consumer goods |

| Industrial Stamping Machine | 180 | 0.01 | 700 | Heavy machinery |

| Custom Stamping Solutions | 160 | 0.008 | 650 | Aerospace components |

| Automated Stamping Line | 220 | 0.007 | 1200 | Industrial manufacturing |

| Tabletop Stamping Machine | 80 | 0.03 | 400 | Small parts |

| Manual Precision Stamping | 100 | 0.02 | 200 | Craft projects |

| Hydraulic Stamping Press | 250 | 0.005 | 900 | Heavy-duty applications |

When selecting high-quality stamping machines, several criteria should be prioritized to ensure precision and efficiency. One of the most critical factors is the machine's operational accuracy, often quantified by its tolerance levels. According to a report by MarketsandMarkets, the accuracy of a stamping machine can significantly impact production costs, with machines exhibiting tolerances as tight as ±0.01 mm leading to a reduction in scrap rates by up to 30%. Thus, understanding the specifications and capabilities of various machines becomes vital for manufacturers aiming to optimize their production processes.

Durability and maintenance requirements are another key consideration. High-quality stamping machines typically feature robust constructions that withstand prolonged use without compromising performance. The 2022 Industry Forecast indicates that regular maintenance can enhance a machine's lifespan by as much as 40%. Furthermore, ease of access to replacement parts and technical support can minimize downtime, making it essential to consider the service network and availability of components when making a purchasing decision. Ensuring that a machine is designed for easy maintenance can lead to substantial long-term savings and productivity gains in a competitive market.

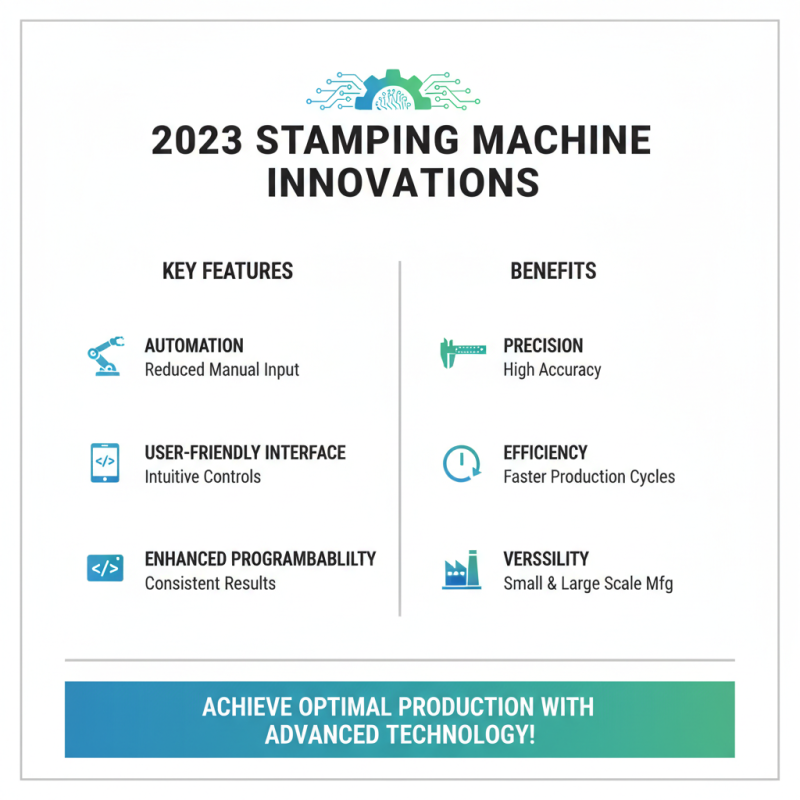

When selecting a stamping machine in 2023, understanding its features and specifications is crucial for ensuring precision and efficiency in production. The top machines this year showcase advancements in automation, providing user-friendly interfaces and enhanced programmability. These features allow operators to achieve consistent results with minimal input, making the machines suitable for both small and large-scale manufacturing environments.

Another notable specification in the leading stamping machines is their versatility. Many models now come equipped with adjustable settings for pressure, speed, and stroke length, allowing users to tailor the machine for specific materials and project requirements. This adaptability not only improves the quality of stamped products but also increases productivity by reducing the need for frequent adjustments. Additionally, the integration of smart technology in some models enables real-time monitoring and diagnostics, ensuring optimal performance and reducing downtime. Overall, these cutting-edge features position the best stamping machines of 2023 as essential tools for modern manufacturing.

When evaluating stamping machines for precision and efficiency in 2023, a comparative analysis of top models reveals a range of features that impact performance significantly. One crucial aspect to consider is the machine's accuracy in producing intricate designs. Many models come equipped with advanced technology that enhances precision through automated adjustments and real-time feedback systems. This ensures that the final output meets strict tolerances required in industries like aerospace and automotive manufacturing, where even minor deviations can lead to costly errors.

Efficiency is another vital metric in selecting stamping machines. The leading models are designed to minimize downtime through user-friendly interfaces and rapid setup procedures. Furthermore, features such as high-speed stamping and energy-efficient motors allow these machines to optimize production cycles without sacrificing quality. Continuous operation capabilities, coupled with robust maintenance features, contribute to overall operational efficiency, making it possible to achieve higher output rates consistently. In sum, the comparison of precision and efficiency in these top stamping machines highlights key innovations that cater to modern manufacturing demands.

This chart compares the precision and efficiency ratings of the top 10 stamping machines in 2023, showcasing their performance metrics across various parameters. The data is derived from industry evaluations and customer reviews.

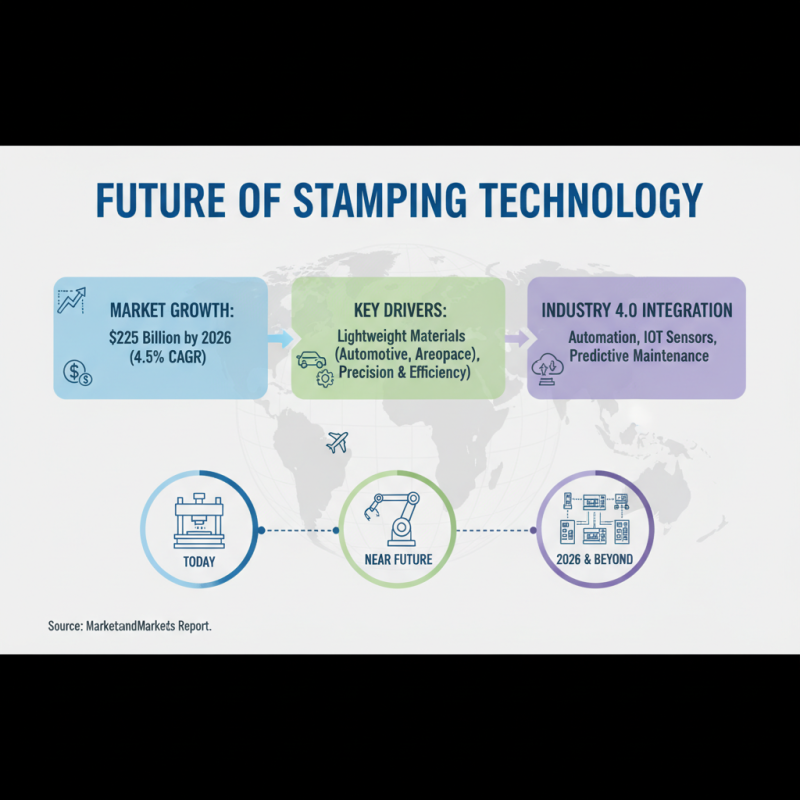

The future of stamping technology is poised for significant advancements driven by the integration of automation and smart manufacturing processes. According to a report by MarketsandMarkets, the global stamping market is projected to reach USD 225 billion by 2026, growing at a CAGR of 4.5%. This growth is largely attributed to the increasing demand for lightweight materials in the automotive and aerospace sectors, which necessitates more precise and efficient stamping techniques. The trend towards Industry 4.0 is also reshaping the landscape, where machines equipped with IoT sensors and advanced analytics provide real-time monitoring and predictive maintenance capabilities, thus enhancing productivity and reducing downtime.

Moreover, innovations in stamping techniques are paving the way for improved efficiency and precision. Techniques such as servo-driven stamping, which allows for variable stroke lengths and speeds, are becoming more commonplace. A report from Grand View Research indicates that the servo press market is expected to witness a considerable rise, reflecting the industry's shift towards more flexible and energy-efficient machines. Additionally, the integration of artificial intelligence and machine learning is enabling more sophisticated data-driven decision-making processes, allowing manufacturers to optimize operations, reduce scrap rates, and achieve tighter tolerances in production. As these technologies evolve, stamping will likely become a pivotal component in achieving greater sustainability and competitiveness in the manufacturing sector.