Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the world of print finishing, the **Hot Foil Embossing Machine** has emerged as a transformative technology, elevating craftsmanship to extraordinary levels. As the demand for unique and luxurious packaging increases, innovations in this arena are becoming paramount. Industry expert John Mitchell, a leading figure in print technology, asserts, “The modern Hot Foil Embossing Machine not only enhances aesthetic appeal but drives efficiency and sustainability in production.” This statement captures the essence of how far this technology has come and its pivotal role in contemporary crafting.

The advancements in Hot Foil Embossing Machines have revolutionized traditional methods, allowing artisans and manufacturers alike to create intricate designs with unparalleled precision. This article delves into the top innovations that are reshaping the industry, showcasing how these machines contribute to a more elegant presentation in everything from luxury packaging to bespoke stationery. By embracing cutting-edge technology, businesses are not only improving their output quality but also setting new standards for design versatility and environmental responsibility. Join us as we explore these remarkable developments that celebrate the artistry and innovation behind hot foil embossing.

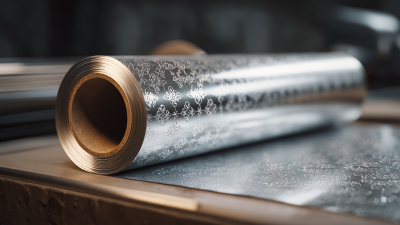

The evolution of hot foil embossing technology reflects significant advancements in both design and functionality, enabling the production of intricate and elegant patterns. Recent breakthroughs have streamlined the hot embossing process, making it more versatile and adaptable to various applications. For instance, Korean researchers have developed a novel technique that allows for the precise imprinting of fine circuit patterns onto flexible polymer substrates, expanding the potential uses of hot foil embossing beyond traditional printing.

This modern approach to hot foil embossing serves as a bridge between artistry and technology, appealing to a wide range of industries, from packaging to fashion. The latest innovations also emphasize sustainability and efficiency, as manufacturers seek to integrate eco-friendly materials and practices into their production lines. With the growing demand for unique and personalized designs, the continuous evolution in hot foil embossing technology promises to inspire creativity while meeting contemporary market needs.

| Feature | Description | Benefits |

|---|---|---|

| Digital Control Systems | Utilizes advanced digital interfaces for precise control. | Enhanced accuracy and reduced setup time. |

| Energy Efficiency | Incorporates energy-saving technologies. | Lower operating costs and reduced carbon footprint. |

| User-Friendly Interfaces | Designed for easy navigation and operation. | Faster training for operators and improved productivity. |

| Multi-Format Capability | Supports various materials and foil types. | Versatility for different projects and applications. |

| Higher Speed Production | Engineered for faster heat-up and operation times. | Increased output and efficiency in production. |

Modern hot foil embossing machines are revolutionizing the way elegance is crafted in various industries, particularly in printing and packaging. These machines incorporate advanced technology that allows for precise control over temperature and pressure, resulting in superior finishes compared to older models. The ability to customize settings for different materials not only enhances performance but also expands the creative possibilities for designers and manufacturers.

One of the key features of contemporary hot foil embossing machines is their user-friendly interface. This technology enables operators to easily adjust settings and monitor process parameters, thereby reducing the learning curve and increasing productivity. Additionally, many of these machines come equipped with automated systems that streamline the embossing process. This automation minimizes manual labor and significantly reduces production times, making it an attractive investment for businesses looking to scale operations efficiently. The precision and consistency offered by modern machines translate to higher quality products that meet the demands of today's discerning consumers.

One of the key features of contemporary hot foil embossing machines is their user-friendly interface. This technology enables operators to easily adjust settings and monitor process parameters, thereby reducing the learning curve and increasing productivity. Additionally, many of these machines come equipped with automated systems that streamline the embossing process. This automation minimizes manual labor and significantly reduces production times, making it an attractive investment for businesses looking to scale operations efficiently. The precision and consistency offered by modern machines translate to higher quality products that meet the demands of today's discerning consumers.

Sustainable practices in the hot foil embossing industry are rapidly gaining traction as manufacturers strive to align with global environmental standards. Recent trends indicate that the push for sustainability is influencing various sectors, including packaging and crafting solutions. According to industry reports, by 2025, over 70% of packaging companies are expected to incorporate biodegradable materials into their production processes, significantly reducing their ecological footprint. This shift towards sustainable materials not only enhances brand image but also meets the growing consumer demand for environmentally-friendly products.

Moreover, innovations in hot foil embossing machines are incorporating these sustainable practices, presenting opportunities for brands to enhance their aesthetic appeal while promoting eco-conscious choices. Many manufacturers are now investing in technologies that utilize recycled substrates and energy-efficient processes, reflecting a broader movement towards sustainability in production. As businesses embrace these advancements, the potential for reducing waste and resource consumption is considerable, paving the way for a more sustainable future in both crafting and packaging industries. The recent recognition of sustainability initiatives showcases the industry's commitment to refining these practices further, indicating a promising trend toward elegance and responsibility in design.

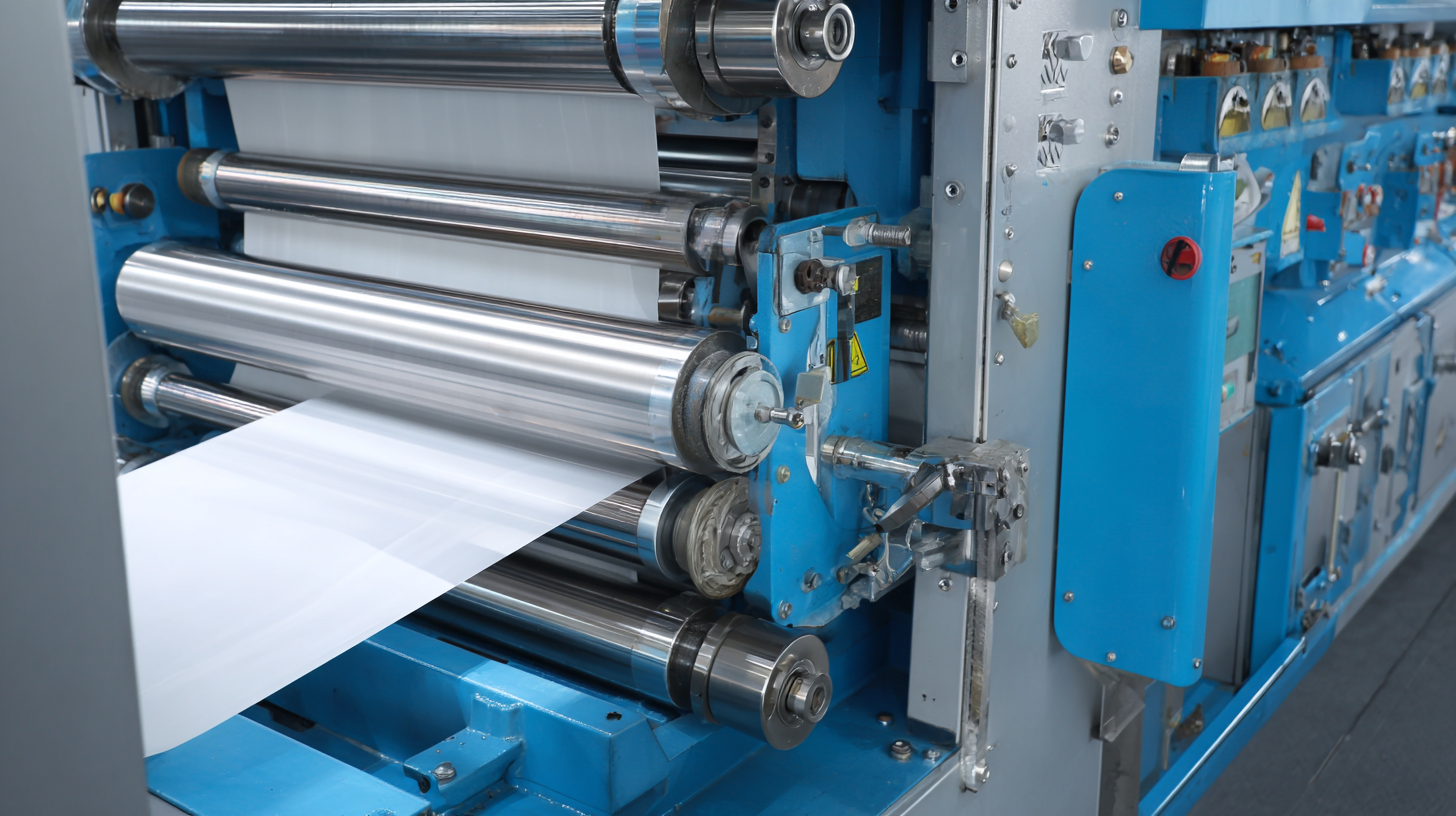

The evolution of hot foil embossing machines highlights a significant shift from traditional techniques to modern innovations, revealing the impact of technology on craftsmanship. Traditional hot foil techniques often relied on manual processes, which limited precision and scalability. The integration of advanced automation and digital controls in modern machines allows for more intricate designs and faster production times, enhancing overall efficiency without sacrificing quality.

Additionally, modern machines offer features like adjustable temperature and pressure settings, enabling artisans to execute a wider range of materials and finishes, thereby broadening creative possibilities.

In contrast, traditional methods emphasize a hands-on approach that values the tactile experience and the unique characteristics imparted by human skill. This craftsmanship fosters a connection to tradition and nostalgia, often sought after in premium products. However, as consumer demand shifts towards customization and faster turnaround times, the benefits of modern hot foil techniques cannot be overlooked.

The comparative analysis of both approaches reveals that while traditional techniques celebrate artisanal values, modern innovations are transforming the landscape, making elegant design more accessible and efficient.

The trends in hot foil embossing technology are rapidly evolving, driven by the demands of creative industries that seek to enhance product aesthetics and differentiation. According to a recent market report by Smithers Pira, the global hot stamping and foil market is projected to grow at a CAGR of 4.7% through 2027, fueled by advancements in machine capabilities and a rising inclination for personalization in packaging. This growth indicates that brands are increasingly investing in finishing techniques that can elevate their products, ensuring that foil embossing remains a desirable option for delivering luxurious touches on materials such as paper, cardboard, and even textiles.

Furthermore, with the integration of smart technology in hot foil embossing machines, businesses can now achieve greater efficiency and precision. The development of computer-controlled mechanisms allows for intricate designs with minimal waste, aligning with sustainability goals that are crucial for modern enterprises. A report from Allied Market Research highlights that 55% of manufacturers are looking for eco-friendly solutions, pushing the industry towards innovations like water-based foils and renewable substrates. As these trends continue to shape the landscape, hot foil embossing is positioned to not only enhance visual appeal but also to contribute to a more sustainable future in creative production.