Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In today’s competitive market, product packaging plays a crucial role in capturing consumer attention and enhancing brand identity. As companies seek innovative ways to stand out, Hot Stamping Printing has emerged as a powerful technique for adding a touch of elegance and sophistication to packaging materials. Renowned industry expert, John Smith, emphasizes this point by stating, "Hot Stamping Printing not only elevates the visual appeal of products but also reinforces the brand's commitment to quality."

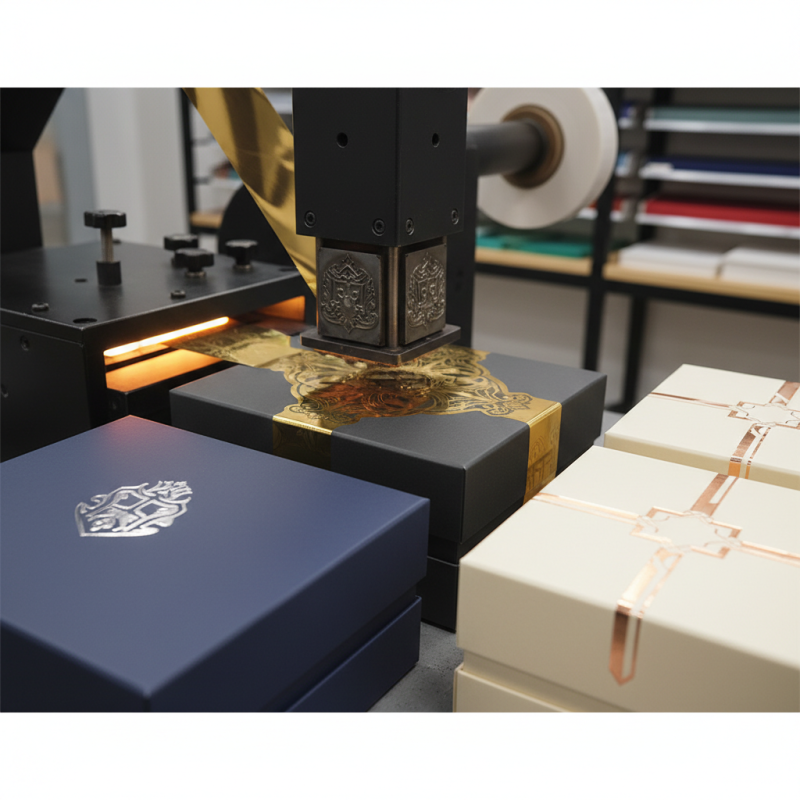

This printing method, which utilizes heated dies to apply metallic or pigmented foil onto surfaces, offers limitless design possibilities and ensures that packaging stands out on the shelves. By integrating Hot Stamping Printing into their packaging strategies, brands can convey a sense of luxury, attract target audiences, and ultimately drive sales. As we delve into the intricacies of this printing process, we will explore how Hot Stamping Printing can significantly enhance your product packaging, setting it apart in a crowded marketplace.

Hot stamping printing has emerged as a popular technique in product packaging, providing a distinct way to elevate the aesthetic appeal of items. This process involves applying a shiny, metallic foil onto packaging using a heated die, resulting in a finished product that is not only visually striking but also adds an element of sophistication. According to a report by Smithers Pira, the global market for hot stamping foil was valued at approximately $1.6 billion in 2020 and is expected to grow at a CAGR of 5.4% through 2025, reflecting a rising demand from various packaging sectors, particularly in cosmetics, pharmaceuticals, and luxury goods.

The technical advantages of hot stamping printing, such as its ability to create durable and high-quality designs, have made it a favored choice among manufacturers. It is noted for its quick application process and the ability to provide intricate designs and vivid colors that resist wear and tear, which is crucial for packaging that needs to stand out on the shelves. A survey conducted by the Packaging Association revealed that 72% of consumers stated they are more likely to purchase a product if the packaging features high-quality finishes like hot stamping. This technique not only strengthens brand identity but also enhances consumer perception, making it a vital component in contemporary packaging strategies.

Hot stamping printing has emerged as a powerful technique used to enhance product packaging, significantly boosting its appeal to consumers. According to the Smithers Pira report on packaging innovations, nearly 60% of product purchasing decisions are influenced by packaging design. Hot stamping offers a striking visual element that can transform ordinary packaging into a captivating presentation. The process involves applying a metallic or pigment foil to a substrate using heat and pressure, resulting in a vivid and high-quality finish that attracts attention on retail shelves.

One of the notable benefits of hot stamping printing is its ability to convey luxury and sophistication. In a study conducted by the Packaging Association, products that utilized hot stamping reported a 25% increase in perceived value among consumers. This technique allows brands to use metallic foils, holographic effects, and vibrant colors, creating an engaging tactile experience that can make a brand stand out in a crowded marketplace. Furthermore, the use of hot stamping can enhance brand recognition and loyalty, as aesthetically pleasing packaging often leads to repeated purchases. As consumer preferences continue to evolve towards unique and appealing designs, hot stamping printing stands out as a valuable tool for brands looking to enhance their product appeal effectively.

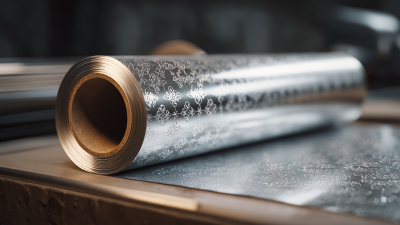

Choosing the right materials for hot stamping printing is crucial for achieving stunning results in your product packaging. The base material, which often includes paper, cardboard, plastic, or even textiles, needs to be compatible with the hot stamping process. It’s essential to select a substrate that can withstand the heat and pressure without compromising quality. For instance, while thicker cardstocks enhance durability, thinner materials may require careful handling to avoid warping or damage during the stamping process.

When considering foil selection, the finish plays a significant role in the final appearance of the product. Hot stamping foils come in various colors and finishes, including metallic, pearlescent, and matte. Each option can evoke different brand emotions; for example, metallic foils can lend an air of luxury, while matte finishes often provide a more modern and subtle look. It is also advisable to test different combinations of substrates and foils to observe how they interact and what effect they create.

Tips: Always conduct a trial run to ensure the materials you’ve chosen adhere properly and yield the desired aesthetic effect. Additionally, keep in mind that environmental factors, such as humidity and temperature, can impact the performance of the materials during the stamping process. Therefore, maintaining a controlled environment is recommended to achieve consistent results.

Hot stamping is a captivating printing technique that can elevate your product packaging by adding a touch of sophistication and differentiation. According to a recent industry report by Smithers Pira, the global market for premium packaging is on the rise, projected to reach approximately $600 billion by 2025. Implementing hot stamping in your packaging design can significantly enhance your brand perception, as consumers are increasingly drawn to packaging that reflects quality and innovation.

To successfully implement hot stamping, start by selecting the right materials. The choice of substrate plays a crucial role; high-quality papers or plastics that can withstand the heat and pressure of the stamping process yield the best results. Next, decide on the design elements—metallic foils in gold, silver, or holographic finishes can add an eye-catching appeal. Research indicates that around 70% of buying decisions are made at the point of sale, making these striking visual elements essential for attracting consumer attention.

Once you've determined your materials and designs, collaborate with experienced professionals to ensure precise execution. The hot stamping process requires specialized machinery, so investing in reliable equipment is vital. Industry reports suggest that companies utilizing hot stamping can see a 30% increase in customer engagement due to enhanced product presentation. By following these steps, you can effectively leverage hot stamping to create memorable packaging that stands out in a competitive market.

Hot stamping printing is an advanced technique that can significantly elevate product packaging, allowing brands to create visually striking designs that capture consumer attention. By applying metallic or pigmented foil onto various substrates, hot stamping not only enhances aesthetic appeal but also adds texture and dimension. According to a recent Smithers report, the hot stamping market is projected to grow by 4.5% annually, illustrating its increasing significance in packaging design. These statistics highlight the trend towards premium packaging as brands seek to differentiate themselves in a crowded marketplace.

To effectively enhance design with hot stamping techniques, several key tips should be considered. First, choosing the right foil is crucial; metallic foils can evoke a sense of luxury, while colored foils can introduce vibrant accents into packaging design. Research indicates that packaging can influence purchasing decisions, with up to 72% of consumers stating that it can affect their choice between similar products. Additionally, incorporating varying finishes, such as matte and glossy contrasts, can further enhance the visual dynamism of stamped elements. Furthermore, combining hot stamping with other printing processes, like embossing or screen printing, can create a multi-layered effect, making packages more tactile and engaging. By understanding and implementing these techniques, brands can create packaging that not only stands out on the shelf but also resonates with consumers on an emotional level.