Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the world of printing and finishing, the choice of the right equipment can significantly impact the quality and appeal of the final product. Foil stamping machines have emerged as essential tools for adding a luxurious touch to various printed materials, from business cards to packaging. As industry expert Mark Thompson, a leading consultant in printing technology, states, "Selecting the right foil stamping machine is crucial for achieving not just visual appeal but also durability in printed designs." This insight highlights the importance of understanding the specific needs and functionalities of different foil stamping machines.

When it comes to enhancing printed materials, foil stamping offers unparalleled precision and vibrancy. However, the selection process can be overwhelming with the multitude of options available on the market. Factors such as machine capabilities, ease of use, and maintenance requirements must be carefully considered. By diving into this essential guide, readers will gain valuable insights on how to choose the right foil stamping machine that aligns with their creative goals and production demands.

In the printing industry, investing in the appropriate foil stamping machine is not merely a matter of aesthetics; it also plays a vital role in defining the operational efficiency of a printing business. Understanding the unique features and benefits of different models will empower printers to elevate their craftsmanship and meet the evolving expectations of their customers.

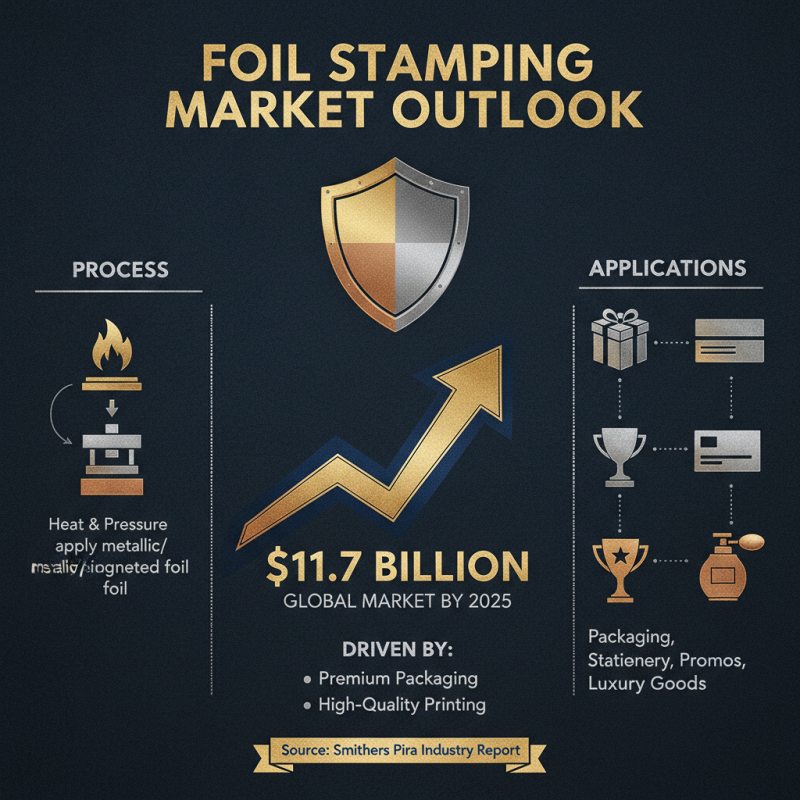

Foil stamping, also known as foil blocking, is a specialized printing process that uses heat and pressure to apply metallic or pigmented foil onto a surface. This technique creates a striking visual effect that enhances the aesthetic appeal of printed materials. Its applications are widespread, ranging from packaging and stationery to promotional items and luxury products. According to a recent industry report by Smithers Pira, the global foil stamping market is anticipated to reach $11.7 billion by 2025, driven by increased demand for premium packaging and high-quality printing solutions.

One of the significant advantages of foil stamping is its ability to produce intricate designs and metallic finishes that standard printing techniques cannot achieve. This capability allows businesses to stand out in a competitive market, offering unique visual elements that capture consumer attention. Research indicates that incorporating foil stamping can increase perceived value and customer engagement, as noted in a study from the Paper and Packaging Board, which found that 66% of consumers are influenced by high-quality packaging. Consequently, understanding the technical aspects of foil stamping, including machine capabilities and material compatibility, is essential for businesses looking to leverage this impactful printing method effectively.

Foil stamping machines come in various types, each designed to meet specific production needs and applications. The most common types include flatbed, rotary, and digital foil stamping machines.

Flatbed machines are ideal for smaller batches and detailed work, as they allow for precise imprints on flat surfaces. These machines are often favored by artisan printers and small businesses due to their versatility and ease of use.

On the other hand, rotary foil stamping machines are built for high-speed production and larger volumes, making them a popular choice for commercial printing operations. They operate in a continuous flow, which increases efficiency and minimizes downtime.

Digital foil stamping machines, meanwhile, represent a more modern approach, integrating digital printing technology with foil application. They offer the advantage of quick setup times and the ability to handle customized designs, making them suitable for short runs and variable data printing.

When choosing a foil stamping machine, it's important to consider the specific needs of your business. Factors such as production volume, project complexity, and budget will influence your decision. By understanding the different types of foil stamping machines available, you can make an informed choice that aligns with your operational requirements.

When selecting a foil stamping machine, several key features should be evaluated to ensure you make the right choice for your business needs. First and foremost, consider the machine’s compatibility with various substrates. According to industry reports, roughly 70% of packaging materials today utilize foil stamping, which underscores the need for versatility in applications ranging from paper and cardboard to plastics. A machine that can handle a broad range of materials will provide greater flexibility and opportunities for your projects.

Another crucial factor to evaluate is the machine's ease of use and setup process. As noted in a recent market analysis, user-friendly machines can significantly reduce production time and minimize errors. Look for machines with intuitive controls and minimal setup requirements to enhance productivity. Additionally, consider the size and footprint of the machine, especially if space is a concern; compact models have become increasingly popular among businesses with limited operational areas.

Tips: When shopping for a foil stamping machine, always review customer feedback and performance reviews. It's also beneficial to attend trade shows or demo days to witness various machines in action. Ultimately, investing time in understanding the features that matter most to your production goals can lead to more informed decision-making and long-term satisfaction with your purchase.

When choosing a foil stamping machine, the first consideration should be the volume of production. According to industry data, businesses that require high-volume output, typically over 10,000 impressions per month, benefit from investing in automatic or semi-automatic machines. These machines can significantly increase efficiency and reduce turnaround times, ensuring that large orders are met promptly. On the other hand, if your needs are more modest, such as low-volume artisanal projects or occasional use, a manual machine may suffice, allowing for flexibility without overwhelming upfront costs.

Material compatibility is another critical factor to assess. Foil stamping can be performed on various substrates, including paper, cardboard, and plastics. A report from the Foil Stamping Institute indicates that about 70% of foil stamping applications are performed on paper products, while the remainder utilizes alternative materials. Understanding the types of materials you want to work with can narrow down your options and ensure that the machine you choose can accommodate your specific needs.

Budget considerations cannot be overlooked. The cost of foil stamping machines can range significantly, with entry-level models priced below $2,000 and advanced systems exceeding $50,000. A survey conducted by the Print Industry Association revealed that nearly 40% of small to mid-sized printing businesses plan to invest between $5,000 and $20,000 in new equipment over the next year. Balancing your production goals with your financial capacity is essential to making an informed decision that aligns with both your current capabilities and future growth potential.

Foil stamping machines are essential tools for businesses looking to enhance their branding and product aesthetics. However, ensuring their longevity requires proper maintenance and care. According to industry research, consistent and thorough upkeep can increase the lifespan of these machines by as much as 30%. Regular maintenance not only helps avoid costly repairs but also ensures optimal performance, allowing for better print quality and efficiency.

One fundamental tip is to maintain a clean working environment. Dust and debris can hinder the stamping process, leading to faulty impressions and increased wear on machine components. Regularly check and clean the machine’s interior, and ensure that the foil feeds smoothly without obstructions. Additionally, lubricating moving parts as per the manufacturer’s guidelines significantly reduces friction, which is crucial for maintaining the machine's precision and performance.

Another important aspect is to monitor the temperature and humidity levels in your workspace. Extreme conditions can affect the quality of the foils and how they adhere during stamping. Keeping a consistent climate helps maintain the integrity of your materials and equipment. It is advisable to invest in a climate-controlled workspace to prevent inconsistencies that could lead to premature wear and tear on the machine. By incorporating these maintenance practices, businesses can extend the life of their foil stamping machines and maximize their investment.