Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

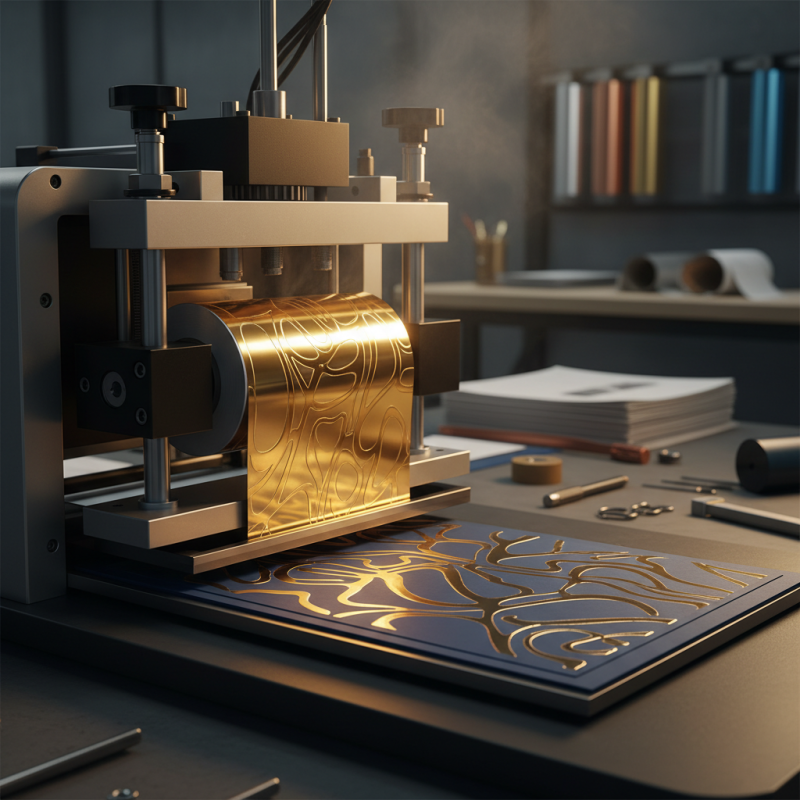

In the realm of printing and packaging, the "Foil Embossing Machine" stands out as a sophisticated tool. Expert John McCarthy, a leading figure in this industry, emphasizes its importance: "A foil embossing machine transforms ordinary materials into extraordinary artwork." This device enhances the visual appeal of products through a unique process.

At its core, the foil embossing machine uses heat and pressure to apply foil onto surfaces. The result is a striking contrast that captures attention. Many industries, from fashion to publishing, benefit from this technology. However, mastering this machine is not without challenges. Operators must fine-tune settings for optimal results, which can be daunting for beginners.

Additionally, there are environmental considerations. The materials used in foil embossing can impact sustainability. Balancing aesthetics with eco-friendliness is an ongoing concern. As the industry evolves, innovation and responsibility must go hand in hand. Understanding the intricacies of the foil embossing machine is crucial for progress.

Foil embossing is a captivating printing technique that enhances the visual and tactile appeal of printed materials. This method uses heat and pressure to apply metallic or pigmented foil onto surfaces such as paper or cardboard. It creates a striking contrast that can elevate branding or packaging. According to a 2022 industry report, the demand for foil embossing in packaging is expected to grow by about 4.5% annually. This highlights the increasing interest in premium packaging solutions.

In practice, foil embossing combines visual aesthetics with functionality. The process involves intricate designs that can draw attention. However, achieving precision can be challenging. Common issues like misalignment or incomplete adhesion may occur. As a result, operators need expertise and patience. Interestingly, companies reported that about 15% of foil projects encounter some form of complication, indicating a trend towards continuous improvement in techniques and machinery.

Moreover, the choice of materials plays a crucial role in the effectiveness of foil embossing. A well-suited substrate can enhance the final outcome, creating a more luxurious feel. Many designers find that experimenting with various foils can yield surprising results. Ultimately, foil embossing is not just about aesthetics; it’s a blend of art and technology that invites both creative exploration and technical refinement.

A foil embossing machine consists of several key components that work together to create stunning designs. The primary components include the heating unit, the embossing plate, and the foil roll. Each part plays a crucial role in the process of pressing metalized foil onto paper, plastic, or other materials.

The heating unit applies the necessary temperature to activate the adhesive on the foil. Reports indicate that proper temperature control is vital for achieving optimal results. Typically, temperatures should range between 250°F to 400°F, depending on the substrate used. A mismatch in these settings can lead to poor adherence or burnt materials.

The embossing plate features engraved designs that transfer the image onto the foil. Precision is key; a poorly designed plate could yield uneven results. The foil roll is another integral element, varying in thickness and color. In recent years, the foil embossing market has seen growth, with the demand for personalized products increasing. This trend has highlighted possible gaps in machine capabilities, prompting manufacturers to innovate further. Operators need skills to adjust machines, ensuring quality and consistency. Attention to detail in every component is paramount for successful foil embossing.

Foil embossing is a fascinating printing technique. It adds a touch of elegance to materials, especially in packaging and stationery. This process involves several key steps. First, a design is etched onto a metal plate. Then, heat and pressure apply a layer of foil onto the surface. The results can be stunning and visually striking.

According to industry reports, the foil embossing market has shown promising growth. The demand for customized packaging has fueled this trend. In recent years, the market grew by approximately 4.5% annually. Companies focus on creating unique designs to stand out. Foil embossing allows for intricate patterns and textures that enhance brand visibility and appeal.

However, the process is not without its challenges. Equipment calibration is crucial. Poor alignment can ruin an entire batch. This underscores the need for experienced operators. Additionally, selecting the right foil is essential. Variations in temperature and pressure affect the final look. These elements require careful consideration to ensure optimal results. While foil embossing is breathtaking, it demands precision and constant quality checks.

This bar chart illustrates the time taken for each step in the foil embossing process. Understanding these durations can help optimize production efficiency and workflow.

Foil embossing is widely applied across various industries, enhancing products with texture and shine. It adds a touch of luxury to packaging. The beauty of foil can be seen on greeting cards, invitations, and business materials. Designers often use foil embossing to make key elements stand out.

In the fashion industry, foil embossing can elevate apparel tags and promotional materials. This method captures attention, making items feel exclusive. It is a fantastic way to communicate brand identity. Foil embossing improves the aesthetic appeal of custom boxes. Brands invest in this technique for its eye-catching results.

**Tips:** When considering foil embossing, think about color combinations. Some colors work better together than others. Experiment with different foil textures to see which suits your needs. You'll find that not every design translates well to foil. Embrace trial and error for the best results.

| Application Area | Description | Benefits |

|---|---|---|

| Packaging | Used to create high-end packaging for products like cosmetics and premium food items. | Enhances aesthetic appeal and brand value. |

| Greeting Cards | Applied in decorative elements for greeting cards, invitations, and stationery. | Adds a touch of luxury and personalization to cards. |

| Book Covers | Used for embossing titles and graphics on book covers. | Increases visibility and appeal on shelves. |

| Labels | Applied on various product labels for a unique finish. | Differentiates products in the market. |

| Business Cards | Enhancements on business cards to make them stand out. | Increases professionalism and memorability. |

Foil embossing machines are transforming the printing industry. They offer unique advantages that cannot be overlooked. According to a recent industry report, businesses using these machines see up to a 30% increase in product appeal. Enhanced visual effects create a luxury feel that attracts consumers. The tactile experience of embossed foil adds value to printed materials, influencing purchasing decisions.

These machines also increase production efficiency. Recent surveys indicate that integration of foil embossing can reduce processing time by 20%. This efficiency doesn't compromise quality. Instead, it allows brands to offer more intricate designs without sacrificing speed. Businesses can create personalized packaging options, which are in high demand. Studies show that brands with customized packaging report 15% higher consumer engagement.

While foil embossing has numerous benefits, there are challenges. Not all materials respond well to embossing. Some types of paper may warp or lose print quality. Adjustments in temperature and pressure settings are vital. Inadequate settings can lead to inconsistent results. Close attention is needed to achieve the desired finish. Despite these challenges, the rewards of using foil embossing machines are considerable.