Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

The Foil Cutting Machine is an essential tool in modern manufacturing and packaging. It precisely cuts foil sheets for various applications. According to industry expert John Smith, "A foil cutting machine transforms material into customizable designs." This highlights its versatility in multiple sectors.

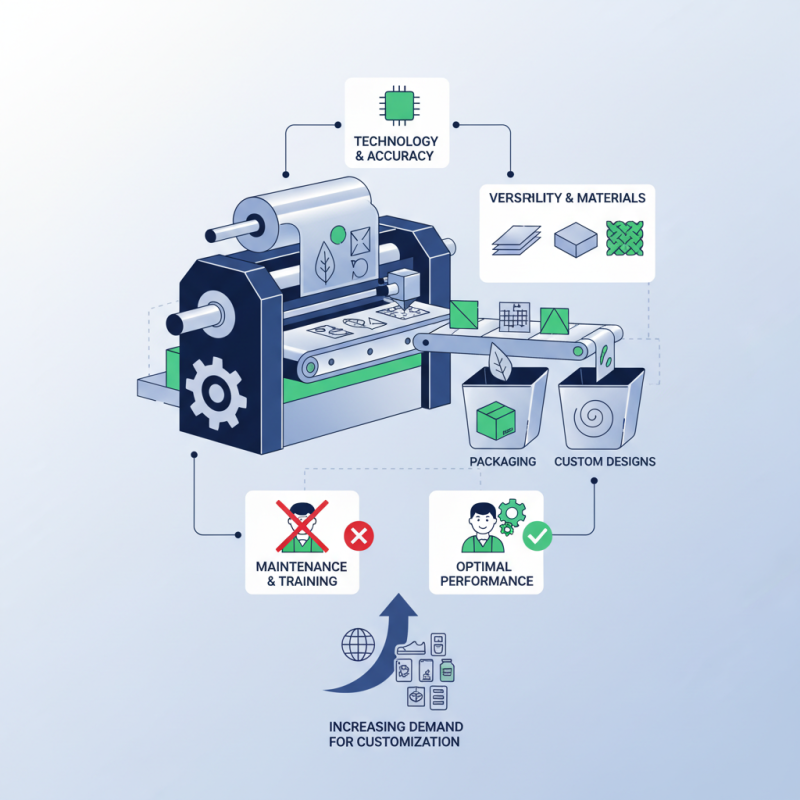

Foil cutting machines employ advanced technology to ensure accuracy. They can handle various materials and thicknesses, making them valuable for different projects. Many businesses rely on these machines to meet their production needs efficiently. However, the complexity of operations can present challenges. For instance, workers must be trained to avoid common errors.

Moreover, maintenance can fluctuate. Regular checks are essential for optimal performance, but many users overlook this. It’s crucial to address these issues for improved efficiency. As the demand for customized products rises, the role of the foil cutting machine becomes increasingly significant. It serves not only as a tool, but as a vital part of the production process.

A foil cutting machine is an essential tool in many industries, especially in packaging and printing. It specializes in cutting your materials with precision. The primary purpose of this machine is to create clean and accurate cuts on foil materials. These could be used for labels, packaging, or decorative elements.

Foil cutting machines operate using a combination of heat and pressure. The foil is placed under a cutting die, which shapes the material precisely. The pressure applied ensures that the cut is clean, leaving no jagged edges. Operators often need to calibrate the machine for different types of foil. This helps maintain the quality of the cuts.

Tips: When using a foil cutting machine, ensure the foil is properly aligned. Misalignment can lead to poor cuts. Regular maintenance of the machine can prevent unexpected breakdowns. Test the machine with scrap material before starting production. This can save time and reduce waste.

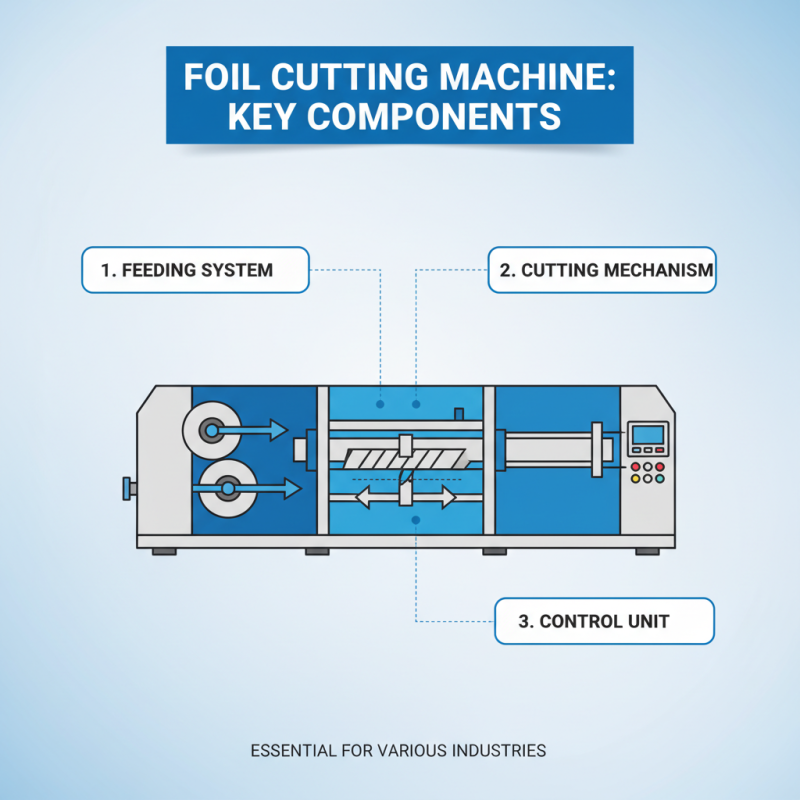

A foil cutting machine is an essential tool in various industries. Understanding its key components helps in appreciating its functionality. The machine primarily consists of a feeding system, a cutting mechanism, and a control unit.

The feeding system ensures precise alignment of foil materials. It often includes rollers that help guide the foil through the machine. Many reports indicate that accurate feeding improves cutting efficiency by up to 30%. This highlights the significance of this component in the overall process.

The cutting mechanism is another critical component. It uses sharp blades to achieve clean cuts. Studies have shown that the quality of blades directly affects the cut's accuracy and smoothness. Less sharp blades can lead to jagged edges, which impact the final product's quality. Meanwhile, the control unit manages the machine's operations. It typically features a user interface for inputting measurements and speeds. This flexibility is vital for adapting to different types of foil materials. However, without proper training, operators may struggle with settings, which could lead to inefficiencies.

Foil cutting machines utilize powerful technology to precisely cut various foil materials. These machines operate on principles that blend both mechanics and automation. Typically, they feature a sharp blade designed to slice through the foil, ensuring clean edges. The alignment of the foil is crucial. If misaligned, the cut can be uneven.

The operation begins with loading the foil material onto a feeding system. This system pulls the foil into the cutting area. Sensors detect the correct position for cutting, ensuring accuracy. Once in place, the blade moves down with force, creating a swift incision. The speed of this process can vary, but speed alone isn't enough for quality cuts. One may find that slower cuts often yield better results.

Careful calibration is essential in these machines. It affects the cutting depth and angle. Additionally, the machine's maintenance can influence performance. A dull blade can lead to frayed edges, a common issue that affects the final product. Regular checks help avoid such pitfalls. Users must stay vigilant in monitoring and adjusting settings to achieve optimal cuts.

Foil cutting machines are essential in various industries. They are widely used in packaging, printing, and electronics. These machines cut foil with precision. Their efficiency is crucial for production lines that require speed and accuracy.

In the packaging sector, foil cutting machines help create attractive, high-quality products. Brands often seek visually appealing packaging. In fact, research shows that packaging can influence consumer decisions by nearly 70%. This statistic underscores the importance of a precise foil cutting process. In electronics, these machines are used to cut conductive foils for circuits. Accurate cuts ensure functionality and reliability.

When operating a foil cutting machine, maintenance is key. Regular checks can prevent costly breakdowns. Always clean the cutting area to avoid material buildup. If you're facing issues with alignment, adjust the guides regularly. These small actions can save time and money.

For those new to the industry, it’s easy to overlook details. Not all machines are created equal. Evaluate the specifications based on your needs. Choosing the right machine impacts production quality and efficiency. Keep testing your processes for improvement. Each small tweak can lead to significant gains.

Regular maintenance of foil cutting machines is crucial for optimal performance. Check the blades frequently for wear. Replace them if they show signs of dullness. Dull blades can lead to uneven cuts and may damage the foil. Cleaning the machine after use is essential. Dust and debris can pile up, affecting functionality. A soft cloth and a gentle cleaner usually do the trick.

Safety should always be a priority. Operators must wear protective gloves to avoid cuts. Standing behind the machine while it operates is advisable. Sometimes, machines can malfunction unexpectedly. Familiarizing yourself with the emergency stop button is vital. Ensure that the workspace is clutter-free. This reduces the risk of accidents while maneuvering the foil or machine. Pay attention to your surroundings for any potential hazards. Regular training for operators can help everyone stay safe and informed.