Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

Choosing the right Foil Embossing Machine can be daunting for business owners. Industry expert John Smith emphasizes, "The right machine can elevate your product’s appeal." This highlights the importance of thorough research and careful selection.

Different machines offer varied features. Some models cater to high production rates, while others focus on precision detail. Consider your specific needs and budget. It’s crucial to avoid getting swayed by flashy advertisements. Real capabilities matter more than claims.

Moreover, user reviews can reveal potential shortcomings. A machine might perform well initially but may present challenges later on. His view serves as a reminder that what works for one business might not suit another. Take time to weigh options carefully. Each choice in a Foil Embossing Machine should align with your long-term goals.

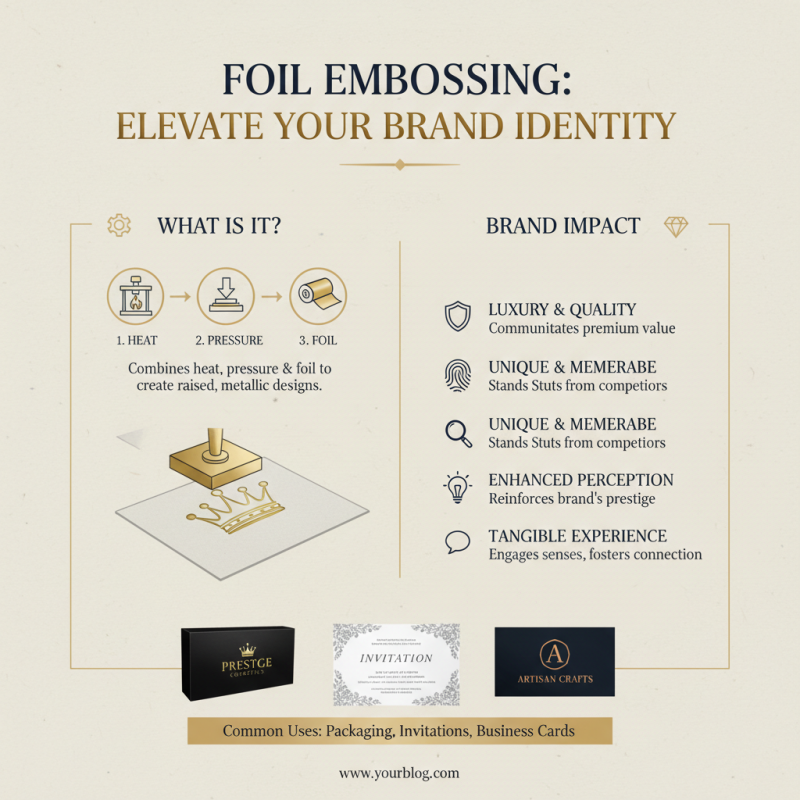

Foil embossing is a captivating technique that adds elegance to various materials. This process combines heat, pressure, and foil to create stunning designs. Many businesses use foil embossing for packaging, invitations, and promotional materials. It makes an impression, but it also raises questions. How does it impact your brand identity?

In a competitive market, standing out is crucial. Foil stamping can enhance your product's aesthetic appeal. Consider using it for luxury items or special events. However, the cost can be a concern. Balancing quality with budget is challenging. If the design isn't thought through, the results might not meet expectations.

Foil embossing requires careful planning. Selecting colors and patterns is vital. Poor choices can lead to disappointing results. Test different combinations before committing. Each detail matters, from foil type to paper choice. A business's success often hinges on such details. Evaluating your needs before investing can save both time and resources.

When choosing a foil embossing machine, it's crucial to focus on the key features that will meet your business needs. One important aspect is the machine's size and capacity. Consider the types of projects you handle. A larger machine may seem appealing, but it requires more space. Think about your work area.

Another key feature is the ease of use. Some machines have intuitive controls, while others can be complex. Training your team can be time-consuming. Moreover, check the heating technology. Consistent heat is vital for quality embossing. An uneven temperature can lead to poor results.

Durability plays a significant role, too. Look for machines made from sturdy materials. A reliable machine can drive your productivity. However, if a machine is too heavy, it may be difficult to move or adjust. These are things to consider carefully. Evaluate your specific requirements against these features to find the right balance for your operations.

When evaluating the

size and capacity requirements for foil embossing machines, consider your business production needs. The machine's size should fit seamlessly into your workspace. A larger machine often means more capacity but might restrict movement or layout. Is there adequate space for operation and maintenance?

Think about the volume of work you plan to handle. A

high-capacity machine is great for large orders. However, it may not be necessary for smaller projects. Many businesses overestimate their needs and regret their choices later.

Balance between current demand and potential growth is crucial.

It’s wise to assess materials too. Foil thickness and type can affect capacity. Different materials require different machine settings. Not all machines can handle every type of embossing job. Analyze your typical projects. They should dictate the machine specifications.

When choosing a foil embossing machine, brand and model differences become crucial. Each brand offers unique features that cater to specific needs. Some machines excel in speed, while others provide better detail in embossing. Understanding these strengths can guide your decision-making.

Look closely at the build quality of various models. Some might feel sturdy but may have a less reliable mechanism. Others might be lightweight and portable, but can struggle with larger jobs. It's key to assess what your business truly requires. Is portability important? Or do you need a machine that handles high volumes?

Consider the control features as well. Some machines come with advanced settings that allow precise temperature and pressure modifications. Others feature simpler controls. While the advanced options seem ideal, they can complicate usage for beginners. Reflect on the balance between ease of use and the versatility you need for your projects. Each choice has its pros and cons, and knowing your priorities can significantly influence your outcome.

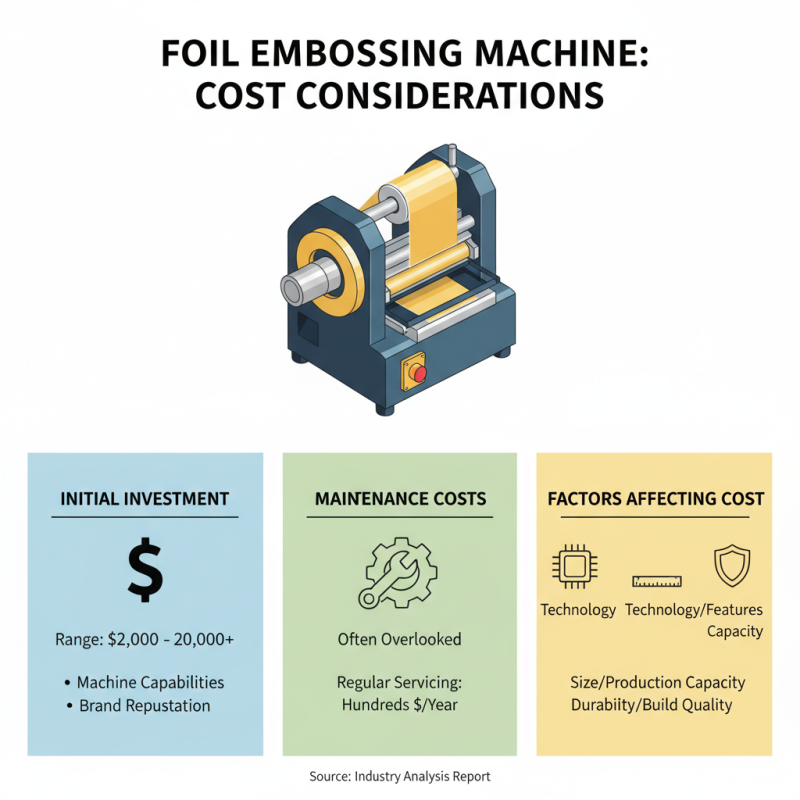

When investing in a foil embossing machine, cost considerations are crucial. The initial cost can range from $2,000 to over $20,000. This wide range depends on the machine's capabilities and brand. Many businesses overlook maintenance costs. Regular servicing can add hundreds per year.

Tips: Consider your production volume. Higher usage may justify a more expensive unit. Evaluate your expected return on investment (ROI). A machine that boosts your production speed can lead to increased profits.

Budgeting for foil embossing also involves understanding the material costs. Foil rolls, which vary in price, add to your operating expenses. Some reports suggest that material costs can account for up to 30% of job costs. Don't forget the costs associated with training staff. Sometimes the cheapest machine is not the best choice if your team needs extensive training.

Tips: Factor in all costs, not just the purchase price. Set aside a percentage for unexpected expenses. This can mitigate financial stress. Remember, the goal is to enhance production while keeping costs manageable. Choose wisely.