Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the rapidly evolving world of packaging, choosing the right Packaging Printing Machine is crucial. According to a recent report by Smithers Pira, the global packaging printing market is projected to reach $500 billion by 2024. This figure highlights the growing demand for high-quality packaging solutions. Industry expert John Doe states, "Selecting the right printing machine can make or break your business's success."

With various technologies available, from flexography to digital printing, brands must carefully evaluate their options. Many companies overlook critical aspects like production speed and maintenance costs. Reports have shown that 30% of businesses regretted their initial equipment choice due to hidden expenses. Neglecting these factors can lead to operational inefficiencies that stunt growth.

Investing in a Packaging Printing Machine is not just about price. It's about understanding your specific needs and long-term goals. Businesses often rush their decisions, leading to misalignment with market demands. In this competitive industry, thoughtful consideration can drive your brand's future success. Each decision must reflect an understanding of current trends and technological advancements. Choosing wisely will set a firm foundation for future expansion.

When selecting a packaging printing machine, understanding your specific needs is crucial. Research indicates that packaging accounts for nearly 30% of the global printing market. The first step is to assess the type of products you will package. Are they fragile? Heavy? Perishable? This evaluation impacts the materials and technology you should consider.

Additionally, the size and design of your packaging play a role. Many businesses overlook the importance of space optimization. A large machine may be tempting, but it could lead to inefficiencies in smaller operations. Reports indicate that small to mid-sized businesses often achieve better results with compact machines.

Lastly, consider your production volumes. High-volume production may require faster, more automated solutions. However, flexibility is also key. Customizable machines can be beneficial for changing product lines. Balancing these facets can be challenging, leading to the question: are you making the best investment for your operation?

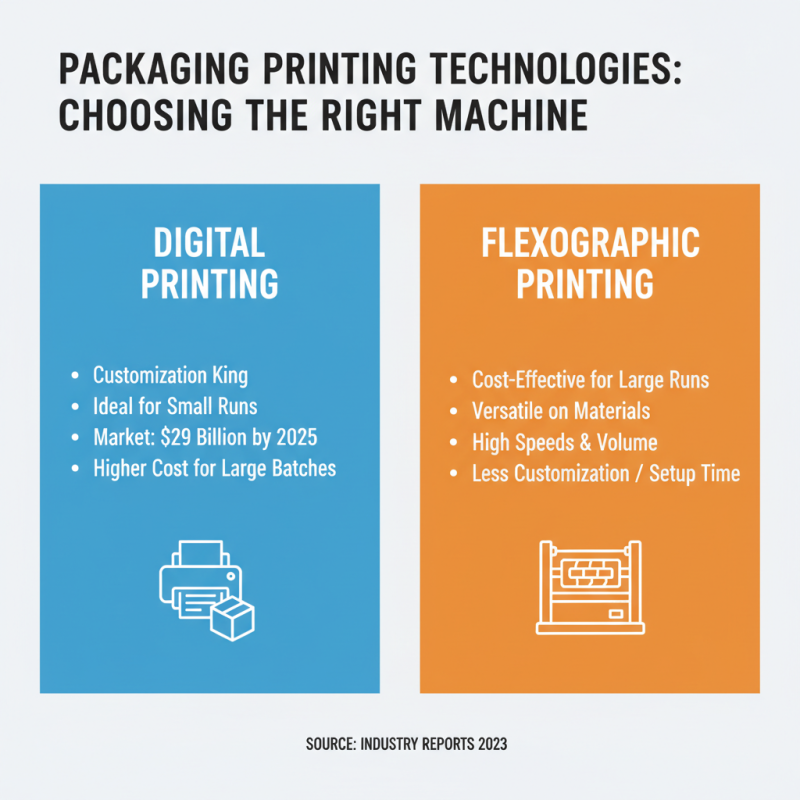

Choosing the right packaging printing machine starts with understanding various printing technologies. Each method has its advantages and limitations. Digital printing is great for customization. Reports state that the digital printing market will reach $29 billion by 2025. It’s efficient for small runs, but costs may rise for larger batches.

Flexographic printing, on the other hand, is versatile. It handles various materials well and is ideal for high-volume production. The Flexographic Technical Association states that this method is growing steadily due to its efficiency. However, setup time can be lengthy, impacting smaller projects.

When evaluating printing technologies, consider the production scale. Ask questions. Can the technology handle your required volume? Also, assess the quality of the output. The 2022 Packaging Technology Report notes that print quality can significantly affect customer perceptions. Inspect sample prints carefully.

Tip: Always analyze your end goals. What type of packaging resonates with your target market? Another tip is to budget for ongoing costs. Maintenance can add unexpected expenses. Many overlook this crucial aspect, leading to financial strain. Reflect on these factors before making a decision.

When considering a packaging printing machine, assessing production volume and speed is crucial. Begin by estimating your daily or weekly output needs. Different businesses have varying demands, and a mismatch can lead to inefficiency. For example, a company producing large quantities might need a machine that operates at high speeds. Conversely, a startup with smaller runs may not prioritize speed but rather flexibility.

Next, think about turnaround times. Quick production can be a game-changer for rapidly changing markets. However, pushing for the highest speed often sacrifices quality. You might find yourself dealing with more waste or errors. This scenario can increase costs and lead to customer dissatisfaction. It’s vital to find a balance that aligns with your specific production requirements.

Evaluate the machine’s capabilities in relation to your goals. If your output volume increases over time, will the machine keep pace? Adjustable speed settings can provide versatility, accommodating both small and large print runs. Reflect on your long-term needs and be cautious of overselling your requirements initially. Choosing the right machine is as much about planning ahead as it is about meeting current demands. Consider these factors carefully for a more informed decision.

| Tip Number | Tip | Production Volume (Units/Hour) | Speed Requirement (Print Speed) |

|---|---|---|---|

| 1 | Assess the types of materials to be used | 1000 | 30 m/min |

| 2 | Determine print quality expectations | 800 | 25 m/min |

| 3 | Evaluate automation features | 1200 | 35 m/min |

| 4 | Consider the machine's footprint | 1500 | 40 m/min |

| 5 | Check maintenance and support offerings | 600 | 20 m/min |

| 6 | Research energy efficiency ratings | 1000 | 30 m/min |

| 7 | Identify flexibility for multiple jobs | 900 | 28 m/min |

| 8 | Understand setup time for changes | 700 | 22 m/min |

| 9 | Analyze cost per print | 800 | 25 m/min |

| 10 | Look at customer reviews and testimonials | 1000 | 30 m/min |

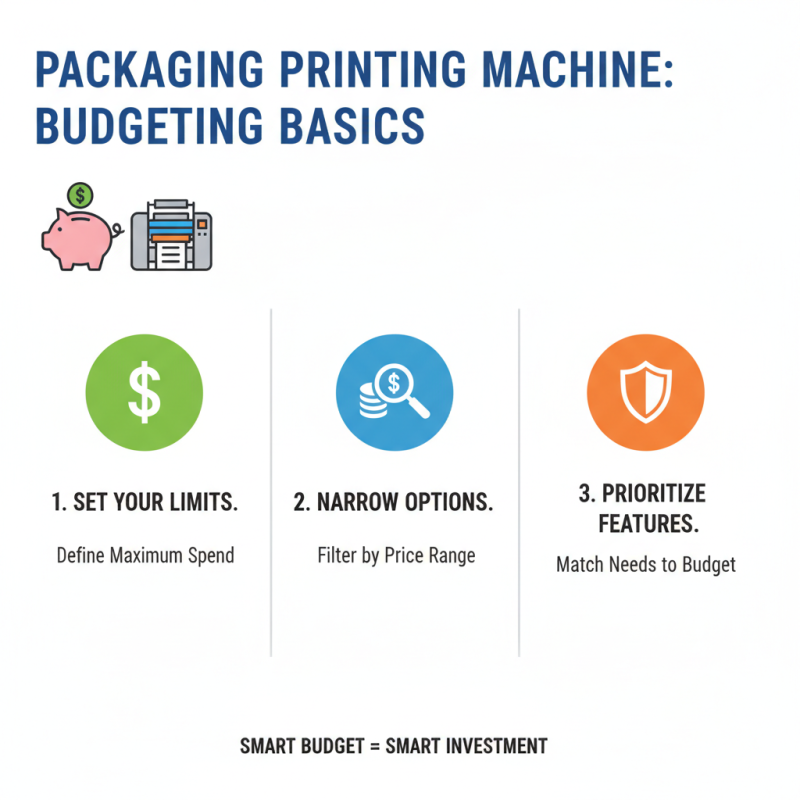

When choosing a packaging printing machine, cost is often a major concern. You must establish a budget before diving into options. This helps narrow down choices and prevents overspending. A well-defined budget allows you to prioritize features that matter most to your business.

Look into machine capabilities that fit your needs. High-quality prints may come at a higher price, but they can attract customers. Balance the initial investment with long-term benefits. Cheap machines could lead to higher costs in maintenance and poor print quality. A careful selection can ultimately save money.

Consider the total cost of ownership. It includes not just the purchase price, but also the supplies, maintenance, and energy costs. Evaluate how frequently you’ll use the machine, too. Investing in a higher-quality machine may be worthwhile if you print regularly. Remember, spending less now may lead to more expenses later. Reflecting on these factors can help you make a more informed decision.

When choosing a packaging printing machine, brand reputation is crucial. Look for manufacturers with a long history in the industry. Online reviews can offer insights into their reliability. Pay attention to feedback, both positive and negative. These reviews can highlight common issues or exceptional service experiences.

Customer support is often overlooked but plays a vital role. A responsive support team can save time and reduce stress. Verify their availability through multiple channels. Some businesses may provide 24/7 support, while others may have limited hours. Check if they offer technical assistance and training. Good customer service can turn a frustrating experience into a manageable one.

Consider how quickly they respond to inquiries. Timely responses often indicate a dedicated support team. Additionally, investigate if they offer on-site support, especially for complex machines. It might seem like a small detail, but timely assistance can ensure a smoother operation. Making a choice without thorough research may lead to regrets later. Customers should reflect on their priorities and think carefully before deciding.