Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

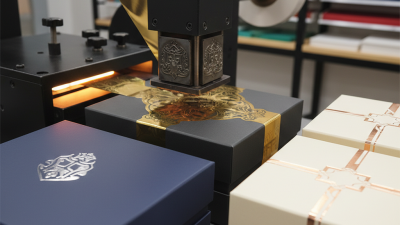

Hot Stamping Printing is a captivating technique that adds elegance to various materials. It involves applying a gold or metallic foil to a surface using heat and pressure. This method has gained popularity in packaging, textiles, and branding. Designers appreciate it for its visual appeal and the luxurious feel it imparts.

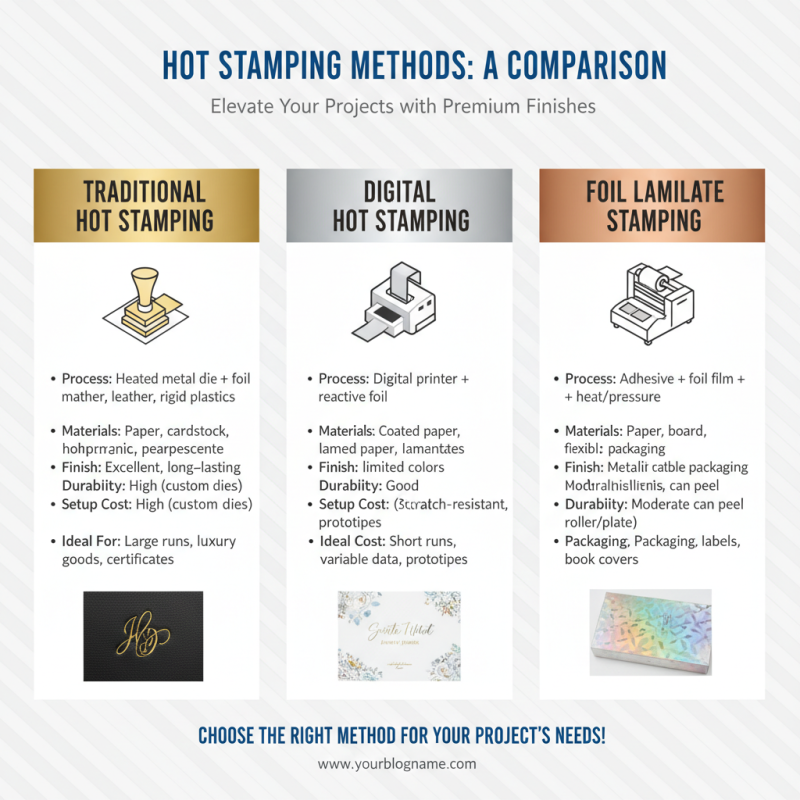

Various hot stamping printing techniques exist, each offering unique benefits. Some methods achieve intricate designs, while others focus on durability. For instance, the roll-to-roll technique ensures high efficiency. However, challenges arise in consistency and quality control. Understanding these methods can help improve outcomes in production.

As you explore the best hot stamping printing techniques, consider your project's specific needs. Each approach has its place in modern design, but not all may suit every requirement. Reflecting on the strengths and limitations of these techniques can lead to better choices in your creative journey.

Hot stamping is a versatile printing technique that enhances various surfaces with metallic or pigmented foil. At its core, this process involves transferring foil onto a substrate using heat and pressure. The results can be strikingly vibrant if done correctly. However, achieving perfect consistency can be challenging.

Understanding the mechanics of hot stamping is crucial. The temperature and pressure settings play a significant role in the quality of the print. Too little heat can result in incomplete transfer, while excessive heat might damage the substrate. Materials used can affect adhesion, leading to issues that require careful monitoring. Many operators find that practice and experimentation are needed to master this art.

Despite its advantages, hot stamping is not without drawbacks. Set-up times can be lengthy, making short runs less viable. Additionally, the process generates waste, which raises environmental concerns. There's always room for improvement and innovation within this technique. A deep understanding of both its potentials and limitations will lead to better outcomes.

Hot stamping is a versatile printing technique used for adding shiny, metallic finishes to various surfaces. The process involves a few key components that contribute to its effectiveness. First, a heated die applies pressure to a foil, transferring the metallic layer onto the substrate. This heat activates the adhesive properties of the foil. Proper temperature settings are crucial. Too hot can scorch the material, while not hot enough may result in poor adhesion.

Another integral component is the substrate material. Different surfaces react differently to hot stamping. For instance, paper, plastic, and leather each have unique properties. Understanding these differences is vital to achieving the desired result. Sometimes, experimentation is necessary. You may need to test various settings to find the optimal combination of heat and pressure. This trial and error is part of the learning curve.

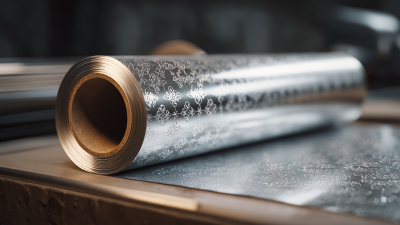

Lastly, selecting the right foil impacts the overall quality. Foils come in various colors and finishes. Each type has its own set of characteristics. Inappropriate foil choice can lead to unsatisfactory results. It's essential to consider the look you want to achieve and the surface you're working on. Ultimately, hot stamping requires an attentive approach, with room for improvement at every step.

Hot stamping is a popular printing technique that adds a touch of elegance and sophistication to various materials. Different hot stamping methods offer distinct advantages and drawbacks. Understanding these differences can be crucial for achieving the desired results in your projects.

One common technique is foil stamping, which involves transferring metallic or pigmented foil onto a surface. It creates vibrant and reflective images. However, achieving a clean transfer can be tricky. Surface preparation is crucial here. A rough or dirty surface can lead to stamping failures.

Thermal transfer, on the other hand, utilizes heat and pressure to imprint designs. This method provides excellent durability. It's great for high-volume jobs, but the initial setup can be time-consuming. A quick tip: always test your design on sample materials before committing to a full run.

Laser stamping is another emerging technique that provides precision and versatility. It allows for intricate designs that other methods struggle to replicate. However, the cost can be higher, and not all materials react well to the laser. Choosing the right substrate is essential for success.

Hot stamping printing is a fascinating technique used across various industries. It involves applying a metallic or pigmented foil to a surface, creating a striking visual effect. Many have embraced this method for packaging design. Its shine grabs consumer attention on shelves. However, the industry needs to keep evolving. Sustainability concerns are pressing. Eco-friendly materials should be prioritized.

The fashion industry often uses hot stamping for branding and product labeling. Think of elegant logos on handbags or striking designs on clothing tags. Yet, not every application is perfect. Some foils can wear off over time, diminishing the quality. In the cosmetic world, hot stamping enhances the luxury feel of products. A sleek finish can influence purchasing decisions, but companies must consider durability.

Event promotional materials frequently utilize this technique in invitations and brochures. The sparkle adds an upscale touch. However, overuse can lead to a cluttered design. Balancing innovation and clarity is essential. Each application reveals the power of hot stamping but also the need for mindful design choices.

Hot stamping printing can elevate your projects, but achieving quality takes practice. Understanding key techniques is crucial. The right temperature and pressure are vital. If either is too low, the foil won’t adhere. Too high, and it may burn. Always conduct test runs to find the sweet spot.

Tips: Experiment with various materials. Some substrates respond better to hot stamping than others. Conduct trials on different papers or plastics. Track your results meticulously. Analyze what works and what doesn’t. This could save time and resources in the long run.

Maintaining equipment is another essential part. Regularly clean the stamping plates. Build-up can affect imprint clarity. A dirty plate may lead to uneven designs. Remember, minor imperfections can cause significant issues in mass production. Reflect on each batch to identify areas for improvement. Aim for consistency, but accept that it may take time to perfect your technique.