Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

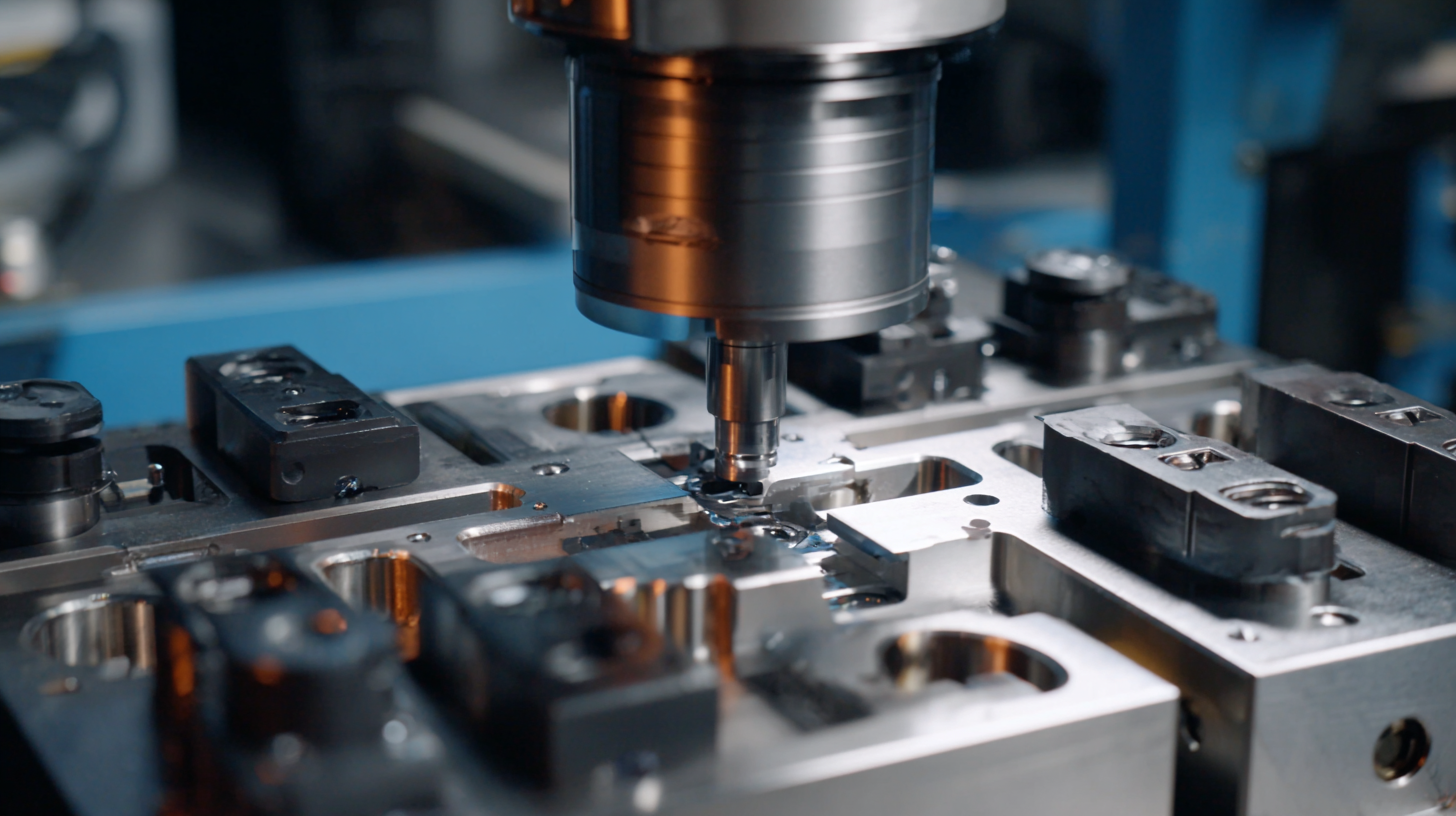

In the dynamic field of manufacturing, the precision of Die Cutting Press techniques plays a pivotal role in enhancing product quality and operational efficiency. According to a report by Smithers Pira, the global market for die-cutting machinery is projected to reach $4.2 billion by 2025, driven by the rising demand for high-precision and customized products across various industries, including packaging and automotive.

As manufacturers strive to meet the growing expectations for accuracy and speed, mastering advanced die cutting techniques has become essential. Effective utilization of Die Cutting Press not only reduces material waste but also streamlines production processes, leading to significant cost savings.

This guide will explore the best practices and innovative strategies that can help businesses achieve unparalleled precision in their die cutting operations, ensuring they remain competitive in an ever-evolving market landscape.

Selecting the right die cutting material is crucial for achieving precision in die cutting press techniques. Materials that have the right mechanical properties significantly affect the accuracy and efficiency of the cutting process. For instance, whether using tool steel or other specialized materials, the decision hinges on their durability and resistance to wear, which directly impacts the longevity of the die and the quality of the finished product.

Recent advancements in material selection methods, such as Fuzzy Multi-Criteria Decision Making (FMCDM), have transformed how companies approach the selection of die materials. By utilizing FMCDM, manufacturers can evaluate multiple criteria—including hardness, toughness, and cost—effectively selecting the most suitable hot forging die tool steel for their specific needs. This methodology not only streamlines the decision-making process but also ensures that the chosen materials align with the precision requirements integral to high-quality die cutting operations.

Die cutting is an essential process in various industries, and achieving precision is crucial to enhance both accuracy and efficiency. One key technique is the use of high-quality dies that are specifically designed for the materials being processed. Precision-engineered dies reduce the risk of deformities and ensure that each cut matches specifications closely. Additionally, maintaining sharp blades is vital; dull blades can lead to uneven edges and inconsistent cuts, ultimately affecting the final product's quality.

Another effective technique to improve die cutting accuracy is the implementation of advanced alignment systems. These systems help operators align materials precisely before cutting, minimizing errors that can occur from misalignment. Utilizing computerized controls with feedback mechanisms allows for real-time adjustments and precise tension settings, further enhancing the cutting process’s accuracy. By adopting these essential techniques, manufacturers can significantly improve their die cutting operations, achieving better results while minimizing waste and downtime.

In the realm of precision die cutting, the integration of advanced software solutions is revolutionizing the industry. The adoption of Computer Numerical Control (CNC) machines has streamlined processes by allowing for high levels of automation and accuracy. This technological shift not only enhances productivity but also enables manufacturers to execute complex designs with minimal human intervention. As businesses seek to optimize their production lines, the reliance on sophisticated software becomes paramount for ensuring precision in die cutting applications.

Furthermore, innovative platforms are emerging that facilitate the seamless interaction between digital designs and cutting machines. These software solutions streamline the workflow from concept to creation, allowing users to manipulate designs easily and achieve precise cuts. Companies are increasingly modernizing their equipment to leverage these technological advancements, underscoring the critical role software plays in achieving high-quality outcomes in die cutting. With each advancement, manufacturers are not only improving efficiency but also setting new standards for quality in the industry.

When it comes to die cutting, precision is key, yet many practitioners fall into common pitfalls that can compromise their results. One frequent mistake is misalignment of the die and material during the cutting process. Just as gardeners must pay attention when deadheading plants to avoid damaging healthy blooms, careful alignment in die cutting ensures that the intended design is executed flawlessly. Taking the time to measure and align materials properly can significantly enhance the quality of the cuts.

Another common error is using a worn-out die or blade, which can lead to jagged edges or incomplete cuts. This is akin to using dull gardening tools that can damage plants rather than promote healthy growth. Regular maintenance and replacement of cutting tools are essential to avoid these issues. By staying vigilant about tool condition and following best practices, professionals can achieve the precision required for high-quality die cuts, ultimately leading to better outcomes and less waste.

In die cutting, precision is paramount to achieving a flawless final product. Evaluating the performance of your die cutting press involves several critical metrics that can help you gauge its effectiveness. Key performance indicators (KPIs) may include the cut accuracy, material waste ratios, and speed of operation. By regularly measuring these metrics, you can identify areas for improvement and ensure your processes are optimized for maximum efficiency.

Tip: Keep a detailed log of your production runs to track these metrics over time. This data can help you spot trends and set benchmarks that will guide your future operations.

Additionally, consistent calibration of your die cutting press is essential for maintaining precision. Regular checks on blade sharpness and alignment minimize discrepancies in cuts and reduce material waste.

Tip: Implement a routine maintenance schedule to ensure that both your equipment and the dies are in top condition, preventing any potential disruptions in the production line.

| Metric | Description | Measurement Unit | Ideal Value | Current Value |

|---|---|---|---|---|

| Cutting Accuracy | Deviation from target dimensions | mm | ±0.1 | ±0.15 |

| Material Utilization | Percentage of material used effectively | % | 90% | 85% |

| Setup Time | Time taken to set up the press | Minutes | 10 | 15 |

| Production Rate | Number of units produced per hour | Units/hour | 100 | 90 |

| Downtime | Time the press is not operational | Hours/week | < 2 | 3 |